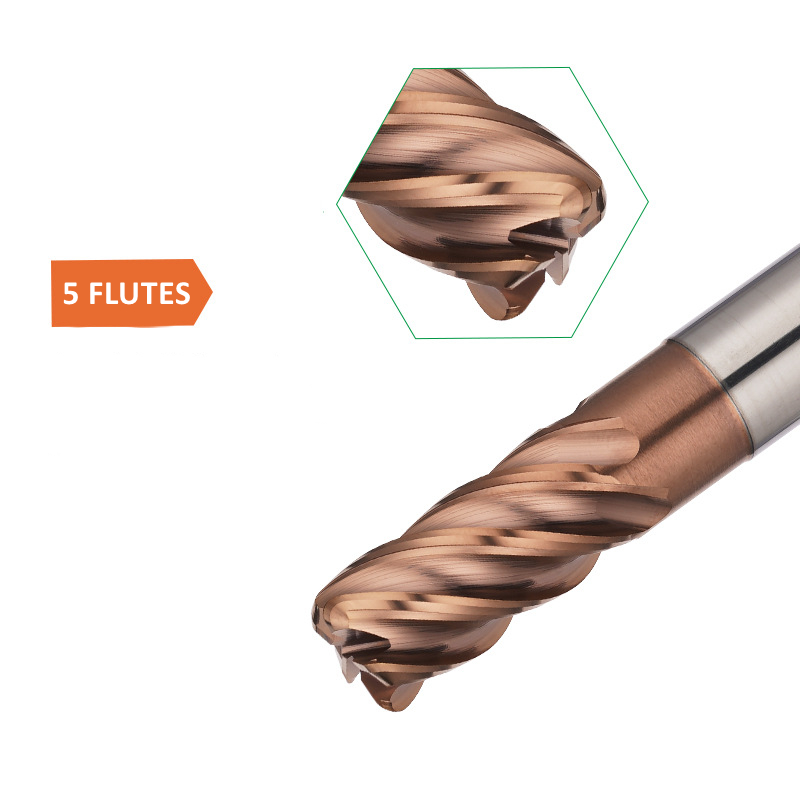

Pob kws Radius Mill Rau Nickel-based High-Temp Alloys

KHOOM PLIG

Titanium yog cov khoom siv tsis zoo rau lub tshuab, tshwj xeeb tshaj yog nyob rau hauv cov cuab yeej hnyav, xws li cov cuam tshuam nrog High Efficiency Milling (HEM). Lub kaum pob hluav taws xob milling cutter tshwj xeeb yog siv rau kev ua cov ntaub ntawv hauv kev lag luam aviation. Nws txais yuav import tungsten steel bar Tshuag thiab muaj lub neej ua haujlwm ntev.

Kev pom zoo rau kev siv hauv chaw ua haujlwm

Titanium alloy TC18-21, ferrite, high-nickel alloy siab tshaj 35%, high-temperature stainless hlau, nickel-chromium-cobalt thiab lwm yam nyuaj-rau-txiav high-lub zog titanium alloys, high-temperature alloy cov ntaub ntawv.

5-flute tsim yog 30% -40% sai dua 3-flute / 4-flute milling cutter

Seismic Tsim / Ultra High Metal Tshem Tawm Tus Nqi / Tsawg Internal Stress

| Flute Diameter | D6-D12 | Flute Length | 8-24 hli |

| Hom Flute | Helical | Khoom siv | Qib siab tungsten |

| Txheej | Yog lawm | Hom | MSK |

| Kev Ua Ntau Yam | Cov ntaub ntawv nyuaj-rau-txiav xws li titanium alloys, superalloys, ferrites, nickel lub cev, high-temperature stainless hlau, thiab npib tsib xee-chromium-cobalt | ||

| Siv tau Machine | Milling tshuab, CNC machining chaw, computer gongs, engraving tshuab | ||

NTAUB NTAWV

1.Tshwj xeeb rau Titanium / superalloy nyuaj-rau-txiav cov ntaub ntawv

Nruab nrog lub siab lubricating thiab tsis tshua muaj kev sib txhuam coefficient los txo qhov kev ntxhov siab sab hauv ntawm cov khoom ua tiav.

2.Geometric Flute

Zoo heev 5-hniav U-groove geometric tsim tuaj yeem ua rau kom muaj kev sib cuag nrog cov khoom siv los ua tiav, thaum ua kom cov cuab yeej rigidity thiab ua kom muaj kev ntxhib los mos zoo heev.

3.Ntshuam tungsten steel bar

Shank kam rau ua qhov tseeb ntawm H5, tshwj xeeb tshaj yog tsim los rau high-precision shank clamping systems.

4.Chamfer tsim

Ua kom yooj yim rau clamped.

5.Seismic Design

Ultra-siab hlau tshem tawm tus nqi, tsis tshua muaj kev ntxhov siab, 30% -40% sai dua li cov tsoos 3-hniav / 4-hniav milling cutters

Daim ntawv thov:

Aerospace, tub rog, mechanical parts, tsheb, tshwj xeeb hauv kev sib txuas lus hluav taws xob thiab lwm yam

Tus neeg yuav khoom ceeb toom:

1. Ua ntej siv lub cuab yeej, thov ntsuas lub cuab yeej deflection. Thaum lub cuab yeej deflection raug tshaj 0.01mm, thov kho nws ua ntej txiav.

2. Qhov luv luv ntawm lub cuab yeej tawm ntawm lub chuck, qhov zoo dua. Yog tias lub cuab yeej tawm ntev dua, qhov ceev, pub tus nqi thiab txiav nyiaj yuav tsum raug txo.

3. Thaum lub sij hawm txiav, yog qhov txawv txav los yog lub suab tshwm sim, thov txo qhov ceev thiab txiav nyiaj kom txog thaum qhov xwm txheej zoo dua.

4. Cov cua txias steel yog nyiam dua cov tshuaj tsuag thiab cua dav hlau, uas tuaj yeem txhim kho kev siv cov tshuab txiav tshuab. Titanium alloys thiab lwm yam superalloys tsis pom zoo.