HRC65 carbide 4 raj nplaim hluav taws xob kawg mills

Khoom Piav Qhia

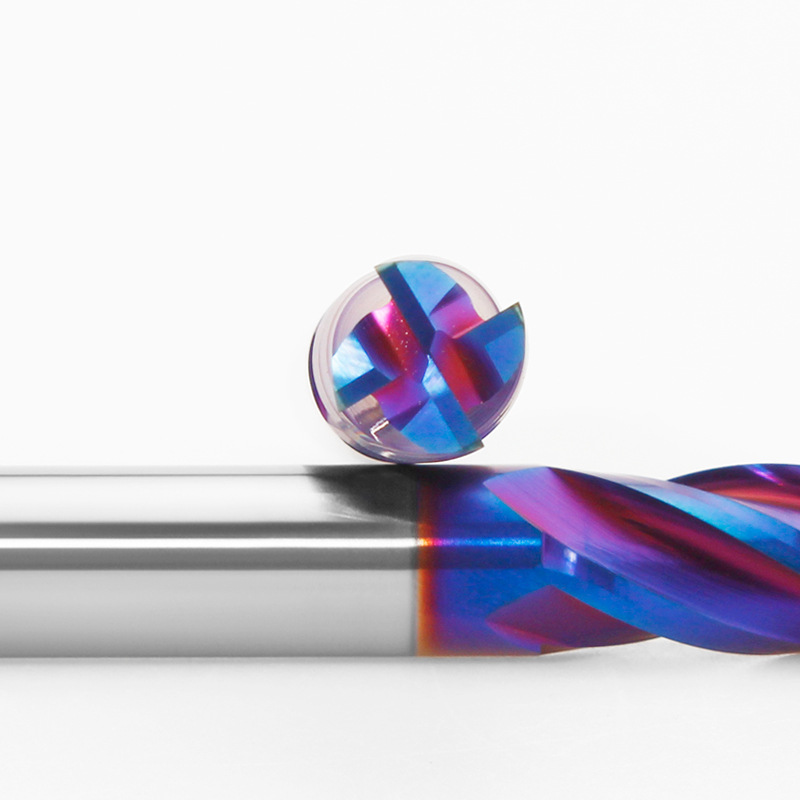

Khoom Txheej: Xiav Nano Txheej

Khoom Siv Khoom: Zoo Siab Tungsten Hlau

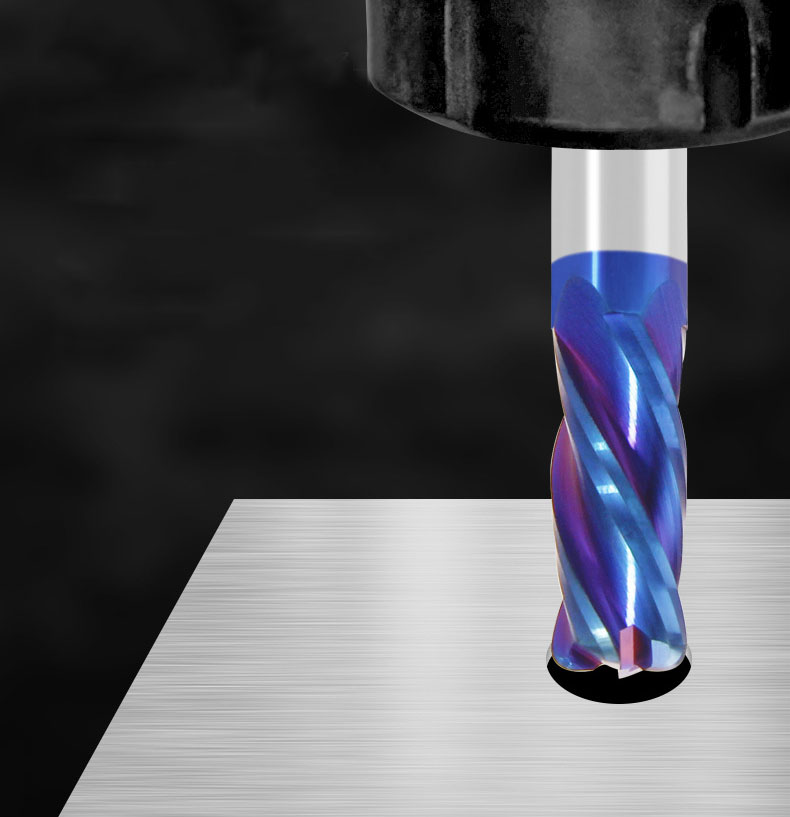

Muaj Peev Xwm Cov Cuab Yeej: CNC Machining Chaw, Engraving Machine, Engraving Machine thiab lwm yam siab ceev machine

TEJ KHOOM: Stainless hlau, tuam hlau, Carbon Hlau, Alloy Steel Thiab Lwm Yam Khoom

Lub ntsiab tseem ceeb: kev siv cov tshiab zoo particle tungsten steel bar, zoo, zoo ntug thiab siab ua cov nyhuv, zoo ua cov nyhuv

Kev pom zoo rau kev siv hauv kev cob qhia

1. Lub ntsej muag kauv hluav taws xob tsim yog qhov tseem ceeb rau kev rho tawm cov khib nyiab pov tseg, tiv thaiv cov cuab yeej los ntawm cov cuab yeej, thiab txhim kho kev txhim kho zoo heev

2. Nyob rau hauv cov xwm txheej ntawm ensuring lub nti qhov chaw, lub loj tub ntxhais txoj kab uas tsim cov cuab yeej ntawm cov cuab yeej thiab txuas ntxiv lub neej pabcuam

| Hom | Msk | Lub npe | Lag luam wholesale av vojvoog kawg |

| Kev nyuaj | HRC65 | Helix lub kaum ntse ntse | 35 degrees |

| Muaj Tshuab | CNC Machining Chaw, engraving machine, engraving machine thiab lwm yam siab kub tshuab | ||

Yam uas pab

Cov Txheej Txheem: Altisin Txheej, Nanotechnology txheej, Hardness Txog 4000hv, Thermal Stability ntawm 1200 "C

General tej tsis:

Txiav Ceev VC = 220 (100-800) m / min

Txiav qhov tob ap = l / 20 (l / 8-3 / 40)

Txiav dav ae = l / 2 0 (l / 4-10)

Tib Ntug Pub F: = 0.15mm (0.02-0.2)

Qhov kev txiav cov roj yuav tsum tau hloov kho kom raug raws li cov khoom sib txawv thiab tawv tawv ntawm cov khoom tiav.

Lub ntsiab tseem ceeb: nrog lub ntsej muag sib zog ntawm 35 degrees, nws muaj qhov muaj zog yoog rau cov khoom siv thiab tawv ntawm cov khoom tiav. Nws yog dav siv hauv cov pwm thiab cov khoom lag luam, nrog kev ua tau zoo siab. Tus ntug yog chamfering, tsis yooj yim rau tawg, thiab yog siv dav hauv kev ceev nrawm.

Why choose us:Sharp blade;improve efficiency;strong and sturdy;complete categories;high quality material;support customization.

Cov Lus Qhia Tshwj Xeeb:

| Yam khoom tsis tau. | Inch d | R | Txiav Ntev | Shank Dev | Zuag qhia tag nrho ntev | Ziab khaub ncaws |

| MSKEM4FB001 | 4 | 0.5 | 10 | 4 | 50 | 4 |

| MSKEM4FB002 | 4 | 1 | 10 | 4 | 50 | 4 |

| MSKEM4FB003 | 5 | 0.5 | 13 | 5 | 50 | 4 |

| MSKEM4FB004 | 5 | 1 | 13 | 5 | 50 | 4 |

| MSKEM4FB005 | 6 | 0.5 | 15 | 6 | 50 | 4 |

| MSKEM4FB006 | 6 | 1 | 15 | 6 | 50 | 4 |

| MSKEM4FB007 | 8 | 0.5 | 20 | 8 | 60 | 4 |

| MSKEM4FB008 | 8 | 1 | 20 | 8 | 60 | 4 |

| MSKEM4FB009 | 8 | 2 | 20 | 8 | 60 | 4 |

| MSKEM4FB010 | 8 | 3 | 20 | 8 | 60 | 4 |

| MSKEM4FB011 | 10 | 0.5 | 25 | 10 | 75 | 4 |

| MSKEM4FB012 | 10 | 1 | 25 | 10 | 75 | 4 |

| MSKEM4FB013 | 10 | 2 | 25 | 10 | 75 | 4 |

| MSKEM4FB014 | 10 | 3 | 25 | 10 | 75 | 4 |

| MSKEM4FB015 | 12 | 0.5 | 30 | 12 | 75 | 4 |

| MSKEM4FB016 | 12 | 1 | 30 | 12 | 75 | 4 |

| MSKEM4FB017 | 12 | 2 | 30 | 12 | 75 | 4 |

| MSKEM4FB018 | 12 | 3 | 30 | 12 | 75 | 4 |

| MSKEM4FB019 | 14 | 0.5 | 35 | 14 | 100 | 4 |

| MSKEM4FB020 | 14 | 1 | 45 | 14 | 100 | 4 |

| MSKEM4FB021 | 16 | 0.5 | 45 | 16 | 100 | 4 |

| MSKEM4FB022 | 16 | 1 | 45 | 16 | 100 | 4 |

| MSKEM4FB023 | 18 | 0.5 | 45 | 18 | 100 | 4 |

| MSKEM4FB024 | 18 | 1 | 45 | 18 | 100 | 4 |

| MSKEM4FB025 | 20 | 0.5 | 45 | 20 | 100 | 4 |

| MSKEM4FB026 | 20 | 1 | 45 | 20 | 100 | 4 |