HRC45 Carbide 2 Flute Standard Length Ball Nose End Mills

KHOOM PLIG

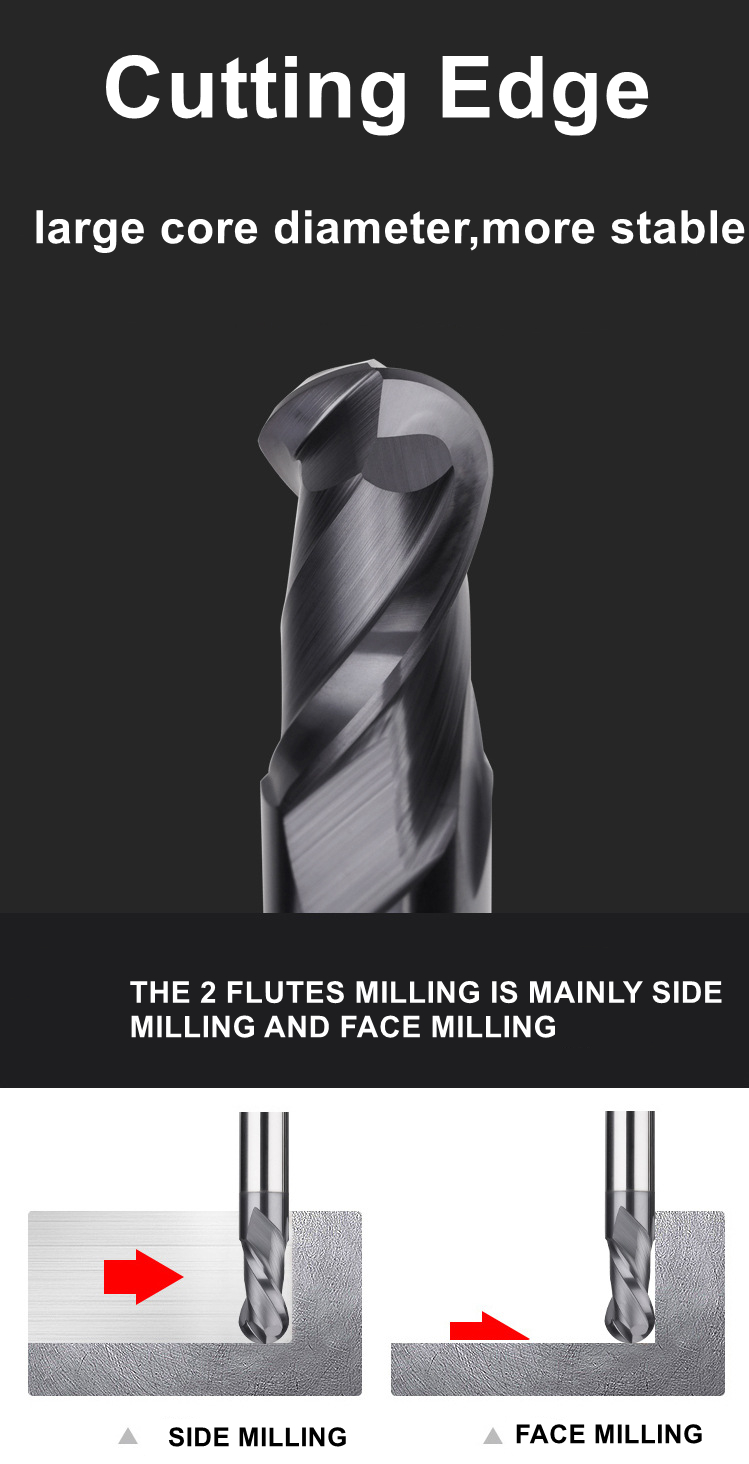

Ua los ntawm txawv teb chaws thawj-chav kawm precision tshuab, lub pob qhov ntswg kawg zeb tuaj yeem zom cov cim kauv ntug lub kaum ntse ntse, cov tub ntxhais loj txoj kab uas hla tsim txhim kho qhov rigidity thiab poob siab tsis kam. Thiab qhov loj nti tshem tawm qhov chaw tsis yooj yim rau khaws nti, tawg riam.

Nws yog ntse thiab hnav-resistant, nti yog smoothly txiav, thiab lub milling efficiency yog zoo dua.

SPECIFICATION

| SIZE | FLUTE DIAMETER D1 (MM) | FLUTE LENGTH L1 (MM) | SHANK DIAMETER D (MM) | TAG NRHO LENGTH L(MM) |

| 1.5 * 4 * 50 | 1.5 | 3 | 4 | 50 |

| 2.0 * 6 * 50 | 2 | 4 | 4 | 50 |

| 2.5 * 8 * 50 | 2.5 | 5 | 4 | 50 |

| 3.0 * 8 * 50 S4 | 3 | 6 | 4 | 50 |

| 3.0 * 8 * 50 | 3 | 6 | 3 | 50 |

| 3.5 * 10 * 50 | 3.5 | 7 | 4 | 50 |

| 4 * 10 * 50 | 4 | 8 | 4 | 50 |

| 4 * 15 * 75 hli | 4 | 8 | 4 | 75 |

| 4 * 20 * 100 hli | 4 | 8 | 4 | 100 |

| 5 * 13 * 50 | 5 | 10 | 5 | 50 |

| 5 * 13 * 50 S6 | 5 | 10 | 6 | 50 |

| 6 * 15 * 50 | 6 | 12 | 6 | 50 |

| 6 * 20 * 75 hli | 6 | 12 | 6 | 75 |

| 6 * 30 * 100 hli | 6 | 12 | 6 | 100 |

| 8 * 20 * 60 hli | 8 | 16 | 8 | 60 |

| 8 * 25 * 75 hli | 8 | 16 | 8 | 75 |

| 8 * 35 * 100 | 8 | 16 | 8 | 100 |

| 10 * 25 * 75 hli | 10 | 20 | 10 | 75 |

| 10 * 40 * 100 hli | 10 | 20 | 10 | 100 |

| 12 * 30 * 75 hli | 12 | 24 | 12 | 75 |

| 12 * 45 * 100 | 12 | 24 | 12 | 100 |

| 14 * 35 * 80 | 14 | 28 | 14 | 80 |

| 14 * 45 * 100 | 14 | 28 | 14 | 100 |

| 16 * 45 * 100 | 16 | 32 | 16 | 100 |

| 18 * 45 * 100 | 18 | 36 | 18 | 100 |

| 20 * 45 * 100 hli | 20 | 40 | 20 | 100 |

| 6 * 30 * 150 hli | 6 | 12 | 6 | 150 |

| 8 * 50 * 150 hli | 8 | 16 | 8 | 150 |

| 10 * 55 * 150 | 10 | 20 | 10 | 150 |

| 12 * 60 * 150 hli | 12 | 24 | 12 | 150 |

| 14 * 65 * 150 | 14 | 28 | 14 | 150 |

| 16 * 70 * 150 hli | 16 | 32 | 16 | 150 |

| 18 * 70 * 150 hli | 18 | 36 | 18 | 150 |

| 20 * 70 * 150 hli | 20 | 10 | 20 | 150 |

| Loj: 7 * 20 * 60 | 7 | 14 | 7 | 60 |

| 9 * 20 * φ10 * 75 | 9 | 18 | 9 | 75 |

| φ11 * 25 * φ12 * 75 | 11 | 22 | 11 | 75 |

| φ13 * 40 * φ14 * 100 | 13 | 26 | 13 | 100 |

| φ15 * 40 * φ16 * 100 | 15 | 30 | 15 | 100 |

ADVANTAGE

1.Tool handle chamfering yog ib qho yooj yim rau kev khiav lag luam.

Yooj yim rau siv, muaj kev sib raug zoo, txhim khu kev tiv thaiv kev vibration thiab txiav ceev ntawm lub milling cutter, thiab clamping yog nruj dua yam tsis muaj slipping.

2.High rigidity, muaj zog hnav tsis kam.