Zoo Zoo HRC 55 Khoom Carbide Reamer rau CNC Tshuab

Qhia peb cov kev txiav-ntug nyuaj alloy pob khawm cutter, khav theeb zoo kawg li hardness ntawm HRC55. Cov cuab yeej no tau tsim kho kom zoo los muab qhov tshwj xeeb durability thiab precision nyob rau hauv ntau yam kev siv. Kev ntsuam xyuas HRC55 xyuas kom meej tias cov hniav tuav nws cov ntse tshaj kev siv txuas ntxiv, lav qhov ua tau zoo thiab txhim khu kev qha. Txawm hais tias koj tab tom ua haujlwm rau cov haujlwm ua haujlwm nyuaj lossis xav tau cov ntawv thov hlau, lub pob khawm no yog tsim los ua kom tau raws li cov qauv siab tshaj plaws, ua rau nws yog ib qho khoom siv tseem ceeb rau cov kws ua haujlwm thiab cov kws tshaj lij. Ua lag luam nyob rau hauv precision thiab ntev nrog peb HRC55 nyuaj alloy pob khawm cutter.

| Flute diam (d) | Flute ntev (L) | Tag nrho qhov ntev (L) | Txoj kab uas hla (D) | Tus naj npawb ntawm flutes (F) |

| 1 | 15 | 50 | 1 | 4 |

| 1.5 | 15 | 50 | 1.5 | 4 |

| 2 | 15 | 50 | 2 | 4 |

| 2.5 | 15 | 50 | 2.5 | 4 |

| 3 | 20 | 50 | 3 | 4 |

| 3.5 | 20 | 50 | 3.5 | 4 |

| 4 | 20 | 50 | 4 | 4 |

| 4.5 | 22 | 50 | 4.5 | 4 |

| 5 | 22 | 60 | 5 | 4 |

| 5.5 | 25 | 60 | 5.5 | 4 |

| 6 | 25 | 60 | 6 | 6 |

| 7 | 28 | 69 | 7 | 6 |

| 8 | 28 | 70 | 8 | 6 |

| 9 | 32 | 80 | 9 | 6 |

| 10 | 32 | 80 | 10 | 6 |

| 11 | 35 | 80 | 11 | 6 |

| 12 | 35 | 80 | 12 | 6 |

| 13 | 50 | 100 | 13 | 6 |

| 14 | 50 | 100 | 14 | 6 |

| 15 | 50 | 100 | 15 | 6 |

| 16 | 50 | 100 | 16 | 6 |

| 18 | 50 | 100 | 18 | 6 |

| 20 | 50 | 100 | 20 | 6 |

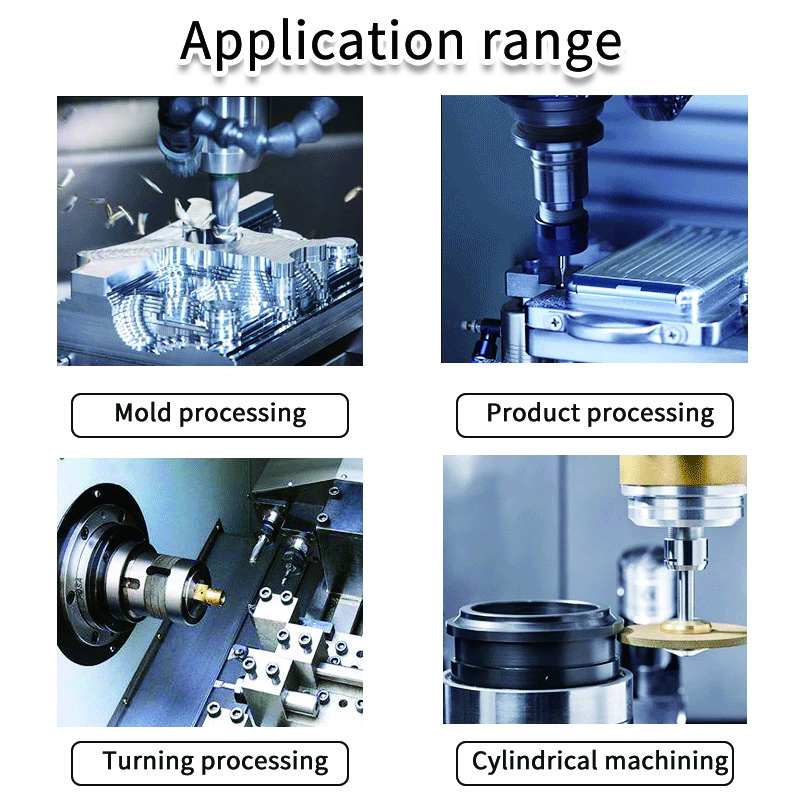

Lub reamer yog ib qho cuab yeej siv tau dav siv hauv kev ua haujlwm hlau rau kev txiav thiab ua ntau yam ntawm cov hlau ua haujlwm. Cov cuab yeej muaj cov hniav ruaj khov thiab tus kov uas ua rau kev txiav ncaj ntawm cov hlau qhov chaw los ntawm kev siv tes los yog cov cuab yeej siv rov ua dua cov hniav.

Cov cuab yeej no ua lub luag haujlwm tseem ceeb hauv ntau yam kev lag luam xws li kev tsim khoom, kev tsim kho thiab tu. Nws cov kev siv ntau yam ua rau nws yog ib qho cuab yeej tseem ceeb hauv cov txheej txheem hlau ua haujlwm, muab kev txhawb nqa tseem ceeb rau cov haujlwm uas xav tau qhov tseeb, kev ua tau zoo thiab ntau yam.

| Hom | MSK | Ntim | Lub thawv yas lossis lwm yam |

| Khoom siv | 20 CrMnTi | Kev siv | Cnc milling tshuab dhos |

| Customized kev them nyiaj yug | OEM, ODM | Hom | NBT-ER |

Cov neeg muas zaub hais li cas txog peb

FAQ

Q1: Peb yog leej twg?

A1: MSK (Tianjin) Txiav Technology Co., Ltd. tau tsim nyob rau hauv 2015. Nws tau loj hlob thiab tau dhau Rheinland ISO 9001

Nrog rau kev tsim khoom thoob ntiaj teb xws li SACCKE high-end tsib-axis sib tsoo chaw nyob hauv lub teb chaws Yelemees, ZOLLER rau lub tshuab ntsuas qhov chaw hauv lub teb chaws Yelemees, thiab PALMARY tshuab cov cuab yeej hauv Taiwan, nws tau cog lus los tsim cov khoom siv high-end, kev tshaj lij, zoo thiab ruaj khov CNC cov cuab yeej.

Q2: Koj puas yog tuam txhab lag luam lossis chaw tsim khoom?

A2: Peb yog cov chaw tsim khoom ntawm cov cuab yeej carbide.

Q3: Koj puas tuaj yeem xa cov khoom mus rau peb tus neeg xa khoom hauv Suav teb?

A3: Yog, yog tias koj muaj tus neeg xa khoom hauv Suav teb, peb zoo siab xa cov khoom rau nws.

Q4: Cov nqe lus them nqi dab tsi tuaj yeem lees txais?

A4: Feem ntau peb txais T / T.

Q5: Koj puas txais OEM xaj?

A5: Yog lawm, OEM thiab customization muaj, peb kuj muab kev cai luam ntawv daim ntawv lo.

Q6: Vim li cas thiaj xaiv peb?

1) Tus nqi tswj - yuav cov khoom zoo ntawm tus nqi tsim nyog.

2) Cov lus teb ceev - tsis pub dhau 48 teev, cov kws tshaj lij yuav muab cov lus hais rau koj thiab daws koj cov kev tsis txaus siab

xav txog.

3) Zoo siab - lub tuam txhab ib txwm ua pov thawj nrog lub siab dawb paug tias cov khoom nws muab yog 100% zoo, yog li koj tsis muaj kev txhawj xeeb.

4) Kev pab cuam tom qab muag thiab kev taw qhia - peb yuav muab kev pabcuam rau ib leeg thiab kev cob qhia raws li koj xav tau.

Lub reamer, ib qho cuab yeej tseem ceeb hauv kev ua kom zoo, ua lub luag haujlwm tseem ceeb hauv kev ua tiav qhov tseeb thiab ua tiav hauv cov tshuab ua haujlwm. Ua ke nrog ib qho yooj yim tab sis sophisticated tsim, tus reamer ua piv txwv txog cov khoom siv tes ua zoo xav tau los ntawm ntau yam kev lag luam. Cia peb nkag siab txog qhov tsis sib xws ntawm cov cuab yeej no, tshawb txog nws cov haujlwm, kev siv, thiab qhov tseem ceeb hauv lub ntiaj teb ntawm machining.

Tsim thiab Cheebtsam:

Ib tug reamer feem ntau muaj ib tug series ntawm tej npoo teem raws ib tug cylindrical lub cev. Cov npoo txiav, feem ntau nyob rau hauv daim ntawv ntawm ncaj los yog helical flutes, yog tsim los tshem tawm cov khoom maj mam li cov cuab yeej tig. Lub cev ntawm cov reamer yog crafted los ntawm high-speed steel, carbide, los yog lwm yam khoom siv ruaj khov, ua kom lub neej ntev thiab ua haujlwm raws li qhov xav tau ntawm machining.

Kev ua haujlwm:

Lub luag haujlwm tseem ceeb ntawm tus reamer yog ua kom zoo dua qub thiab ua kom qhov loj me ntawm qhov drilled yav tas los. Tsis zoo li kev xyaum ua lub qhov, cov reamers muab qhov kov kom tiav, ua kom lub qhov ua tau raws li qhov xav tau ntawm qhov ntev. Lawv tshem tawm cov kev tsis sib xws uas tau tso tseg los ntawm cov txheej txheem drilling, txhim kho qhov tseeb thiab qhov kawg ntawm lub tshuab ua haujlwm. Reamers tuaj nyob rau hauv ntau hom, xws li ncaj-fluted, kauv-fluted, thiab adjustable, txhua tus tsim los ua kom haum rau cov kev xav tau ntawm machining.

Daim ntawv thov:

Lub versatility ntawm reamers pom daim ntawv thov nyob rau hauv ib tug ntau ntawm kev lag luam, xws li aerospace, automotive, kho mob, thiab manufacturing. Nyob rau hauv aerospace thiab automotive engineering, qhov twg precision yog qhov tseem ceeb, reamers yog qhov tseem ceeb hauv kev tsim lub qhov rau cov khoom tseem ceeb xws li cav qhov chaw thiab fasteners. Hauv kev kho mob, qhov chaw tsim khoom cog xav tau qhov tseeb tshaj plaws, reamers pab tsim qhov rau cov khoom siv prosthetic.

Precision Machining:

Ib qho ntawm cov cwj pwm tseem ceeb ntawm cov reamers yog lawv lub peev xwm ua kom muaj kev sib haum xeeb nruj. Cov kws kho tshuab tso siab rau cov cuab yeej no txhawm rau txhawm rau kho qhov ntev ntawm qhov nqaim heev. Lub precision afforded los ntawm reamers yog ib qho tseem ceeb nyob rau hauv kev lag luam uas lub Cheebtsam yuav tsum haum ua ke seamlessly, ua kom pom kev ua haujlwm zoo thiab kev ua haujlwm zoo.

Hom ntawm Reamers:

Cov kev cai sib txawv ntawm machining tau ua rau kev txhim kho ntawm ntau hom reamers. Ncaj-fluted reamers yog qhov zoo rau kev siv lub hom phiaj dav dav, thaum kauv-fluted reamers ua tau zoo hauv cov haujlwm uas yuav tsum tau tshem tawm cov nti zoo. Adjustable reamers muab kev yooj yim hauv kev ua tiav qhov sib txawv qhov ntau thiab tsawg yam tsis tas yuav muaj ntau yam cuab yeej. Txhua hom caters rau tej xwm txheej machining, showcasing lub adaptability ntawm reamers nyob rau hauv ntau yam industrial chaw.

Cov kev sib tw thiab kev txiav txim siab:

Thaum cov reamers tsis muaj nuj nqis hauv kev ua tiav qhov tseeb, cov tshuab ua haujlwm yuav tsum xav txog yam xws li cov cuab yeej sib dhos, nrawm, thiab cov nqi pub kom paub tseeb tias kev ua haujlwm zoo. Kev tuav cov npoo ntse ntse yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig zoo ib yam, thiab kev tshuaj xyuas ib ntus thiab rov ua dua los ua ib feem ntawm kev saib xyuas niaj hnub los txhawb cov txiaj ntsig ntawm cov cuab yeej.

Hauv kev xaus, tus reamer sawv ua pov thawj rau qhov tseeb xav tau los ntawm cov txheej txheem machining niaj hnub. Nws lub peev xwm los ua kom zoo dua qub thiab qhov loj ntawm lub qhov nrog qhov raug thiab qhov zoo ua rau nws yog lub hauv paus hauv kev lag luam uas qhov zoo thiab qhov tseeb tsis tuaj yeem sib tham. Raws li kev siv thev naus laus zis, cov reamer txuas ntxiv mus, hloov mus rau qhov chaw hloov pauv ntawm kev tsim khoom thiab tseem yog ib qho tseem ceeb hauv kev nrhiav kev ua tau zoo hauv precision machining.