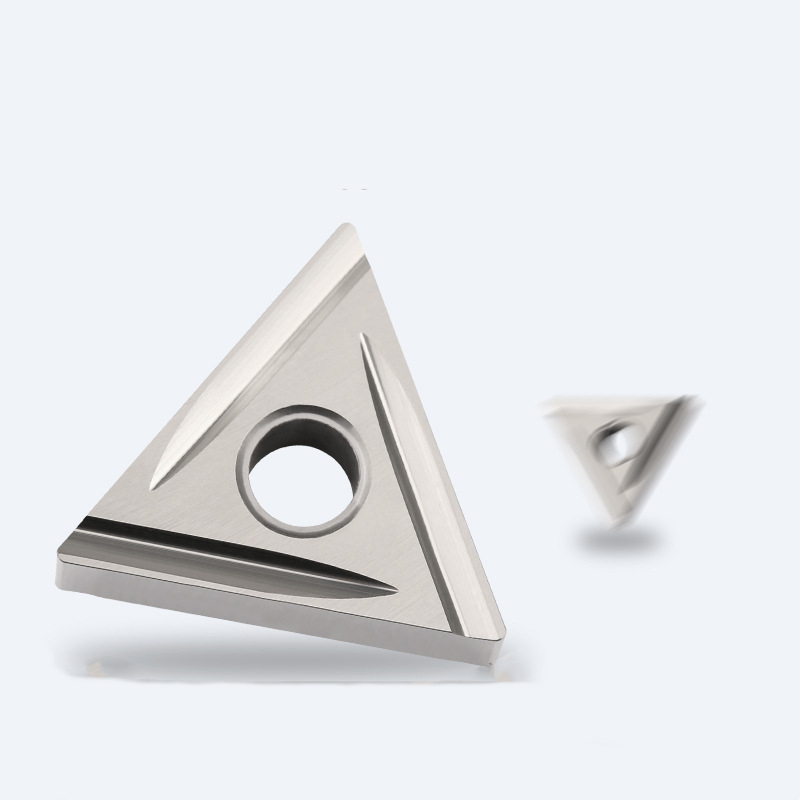

Zoo Zoo Cermet Inserts Rau Tiav Hlau Thiab Stainless

KHOOM PLIG

Nyob rau hauv pem hauv ntej kawg ntawm tus kais dej (xov kais) yog ib tug laum me ntsis, uas yog ib tug high-efficiency kais (xov kais) rau nruam drilling thiab tapping kom tiav kev ua nyob rau hauv ib lub sij hawm.

Nta

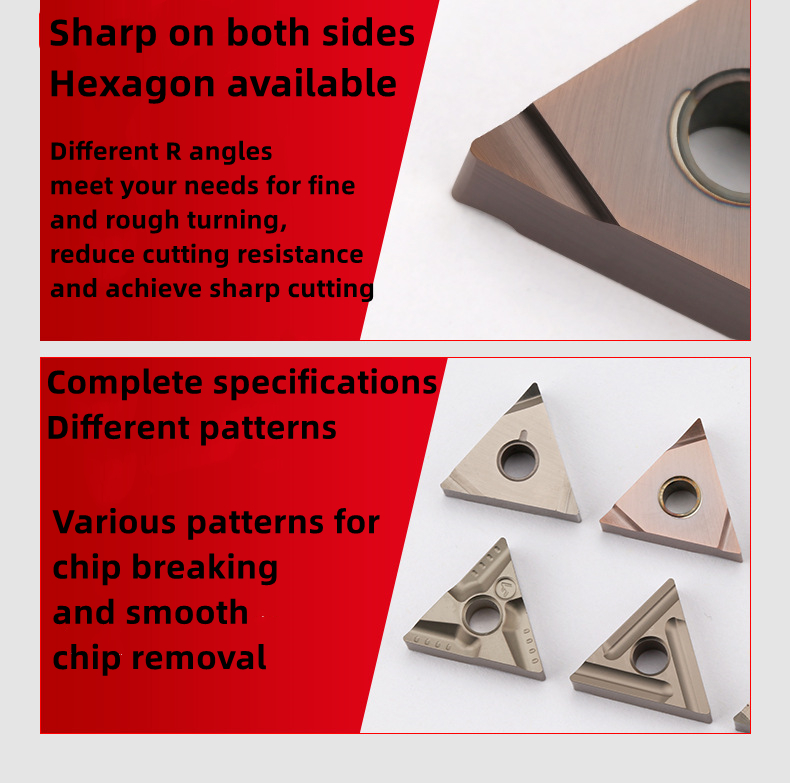

1. Ob tog ntse ntse, Hexagon muaj

Txawv R lub kaum ntse ntse ua tau raws li koj qhov kev xav tau zoo thiab ntxhib tig, Txo kev ua haujlwm siab thiab ua tiav kev txiav ntse

2. Cov qauv sib txawv

Ua kom tiav cov kev qhia tshwj xeeb thiab ntau yam qauv rau nti tawg thiab tshem tawm cov nti du

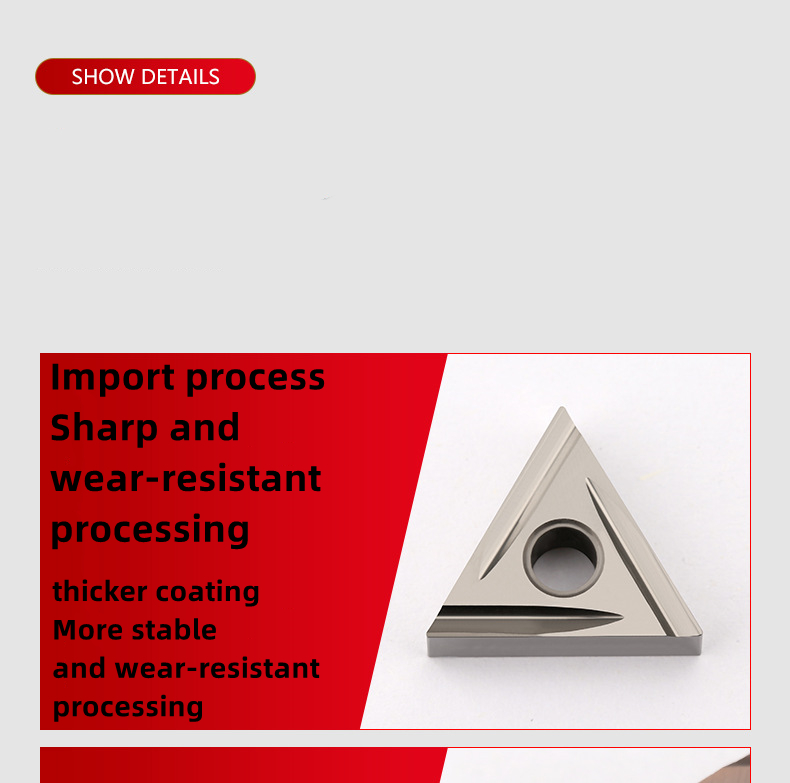

3.Ntshuam txheej txheem

Nyias thiab hnav-resistant, thicker txheej.

Ntau ruaj khov thiab hnav-resistant ua

Tshwj xeeb rau ceramics, hnav-resistant thiab ruaj, siab hardness.

| Hom | MSK | Hom | Milling cuab yeej |

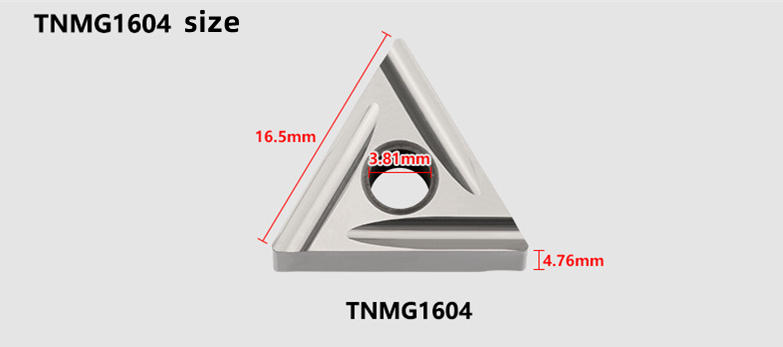

| Khoom npe | Carbide Inserts | Qauv | TIAB SA 160402 |

| Khoom siv | Ceramics | Pob | Lub thawv yas |

CEEB TOOM

Kev tshuaj xyuas ntawm cov teeb meem tshwm sim

1. Rake ntsej muag hnav: (qhov no yog daim ntawv qhia ua ke)

Cov teebmeem: maj mam hloov ntawm qhov workpiece qhov ntev lossis txo qhov ua tiav.

Yog vim li cas: Cov khoom siv hniav tsis haum, thiab txiav cov nyiaj ntau dhau.

Kev ntsuas: Xaiv cov khoom siv nyuaj, txo qhov kev txiav, thiab txo qhov txiav ceev.

2. Teeb meem kev sib tsoo: (daim ntawv tsis zoo ntawm kev ua haujlwm zoo)

Cov teebmeem: Kev hloov pauv sai sai hauv qhov loj me lossis qhov chaw tiav, ua rau muaj qhov tawg ntawm qhov burrs. ,

Yog vim li cas: kev teeb tsa tsis raug, kev xaiv tsis raug ntawm cov khoom siv hniav, tsis zoo rigidity ntawm workpiece, tsis ruaj khov hniav clamping. Kev Ua: Xyuas cov machining tsis, xws li txo cov kab nrawm thiab hloov mus rau qhov hnav-tiv taus ntau dua.

3. Kev tawg hnyav: (daim ntawv phem heev ntawm kev ua haujlwm zoo)

Kev cuam tshuam: tshwm sim tam sim ntawd thiab tsis tuaj yeem tshwm sim, ua rau cov khoom siv khib nyiab pov tseg lossis cov khoom ua haujlwm tsis zoo thiab muab pov tseg. Ua rau: Cov kev ua haujlwm tsis raug teeb tsa tsis raug, thiab cov cuab yeej vibration workpiece lossis cov hniav tsis raug ntsia rau hauv qhov chaw.

Kev ntsuas: Teem qhov tsim nyog machining tsis, txo tus nqi pub thiab txo cov chips los xaiv qhov sib xws machining inserts.

Txhim kho lub rigidity ntawm workpiece thiab hniav.

3. Ua-up ntug

Kev cuam tshuam: Qhov luaj li cas ntawm cov khoom ua haujlwm protruding tsis sib haum, qhov ua tiav ntawm qhov tsis zoo, thiab qhov chaw ntawm lub workpiece txuas nrog fluff lossis burrs. Yog vim li cas: lub txiav ceev yog tsawg dhau, pub tsawg dhau thiab cov hniav tsis ntse txaus.

Kev ntsuas: Ua kom qhov txiav ceev thiab siv cov ntxig ntxig rau qhov pub.