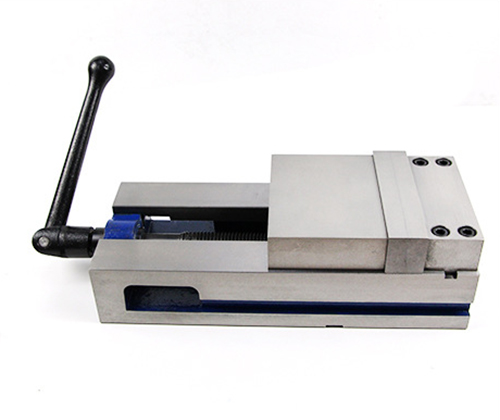

High-Quality Hydraulic Bench QM16M Vises for Precision Milling Applications

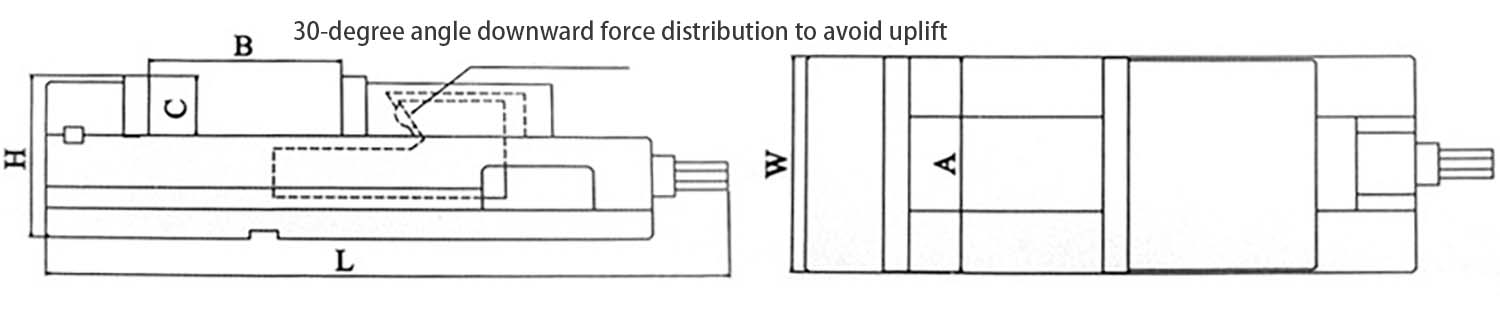

| Model | Jaw width A | Maximum clamping B | Jaw height C | Overall clamp length L | Total width of clamp body W | Total jaw height H | Gross/Net weight |

| Weighted QM1680N | 80 | 75 | 24 | 239 | 81 | 74 | 8/7 |

| Weighted QM16100N | 100 | 110 | 32 | 300 | 101 | 86 | 13/12 |

| Weighted QM16125N | 125 | 125 | 40 | 360 | 126 | 105 | 18/17 |

| Weighted QM16160N | 160 | 190 | 45 | 440 | 161 | 122 | 30/29 |

| Weighted QM16200N | 200 | 200 | 50 | 505 | 201 | 135 | 49/47 |

| Weighted QM16250N | 250 | 250 | 70 | 570 | 251 | 168 | 73/69 |

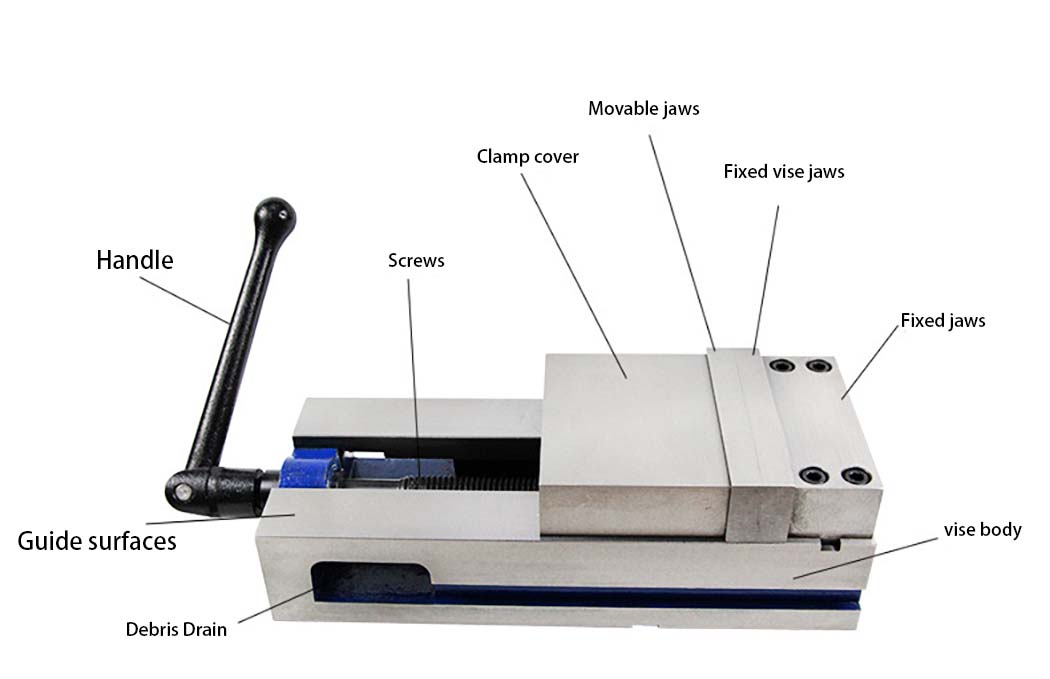

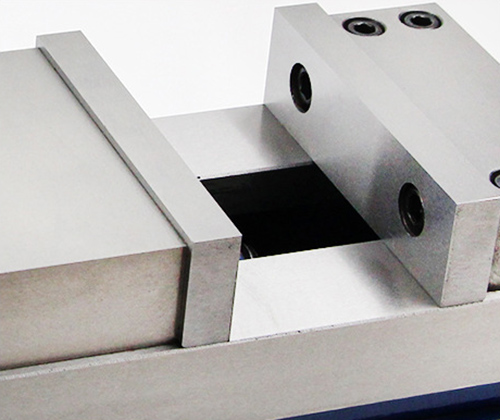

The fixed jaws are fastened by four bolts, which reduces the dynamic deformation.

Thrust bearings are used at the fixed end of the screw to reduce friction and increase clamping force.

Fixed Precision

Parallelism of the clamp body guide facing the bottom surface:0.01/100MM Straightness of the jaws facing the bottom surface:0.03MM Flatness of the clamped workpiece:0.02/100MM

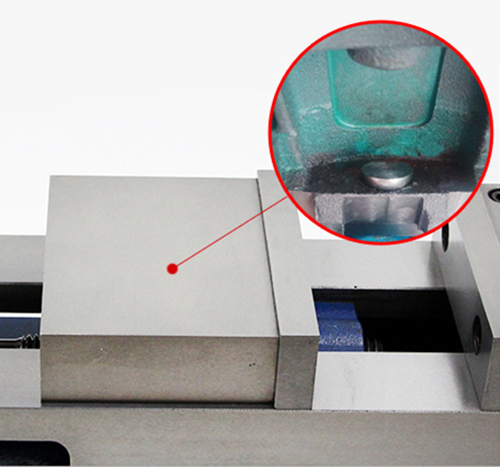

Angle-fixed design

Hemispherical (hardened) poetic design with free force in all directions ensures that the workpiece does not float.

Cast iron clamp body

The clamp body is made of high quality cast iron with fine surface grinding.

Hardened steel jaws

The jaws are made of hardened 45-gauge steel, with a hardness of up to 48HRC, and the jaws are removable for use.

Universal handle

Ductile cast iron with surface treatment for the nut and the handle.

Hardened Screws

The screws are hardened, flamed and blackened to strictly control the cutting precision.

Precision ground guideway surface

The guideway surfaces are precision ground and hardened for a smooth, flat, solid contact surface with a seamless fit.

Solid Craftsmanship, Rock Solid

This type of flat jaw pliers using heavy-duty solid process, the overall body of the pliers for the solid casting materials to ensure the freedom of clamping at the same time, but also take into account the stability of the clamping.

Precautions

The use of the process is not allowed to knock, not allowed to add pry bar casing use, will affect the accuracy and life of its such as if knocking, add pry bar, flat jaw pliers will no longer be warranted. Encountering insufficient clamping force can contact customer service to replace the new product.

When clamping the workpiece, please follow the correct use of the operation, otherwise the vise will no longer warranty.

Clean and oil the vise on time to prevent rusting and prolong the service life.

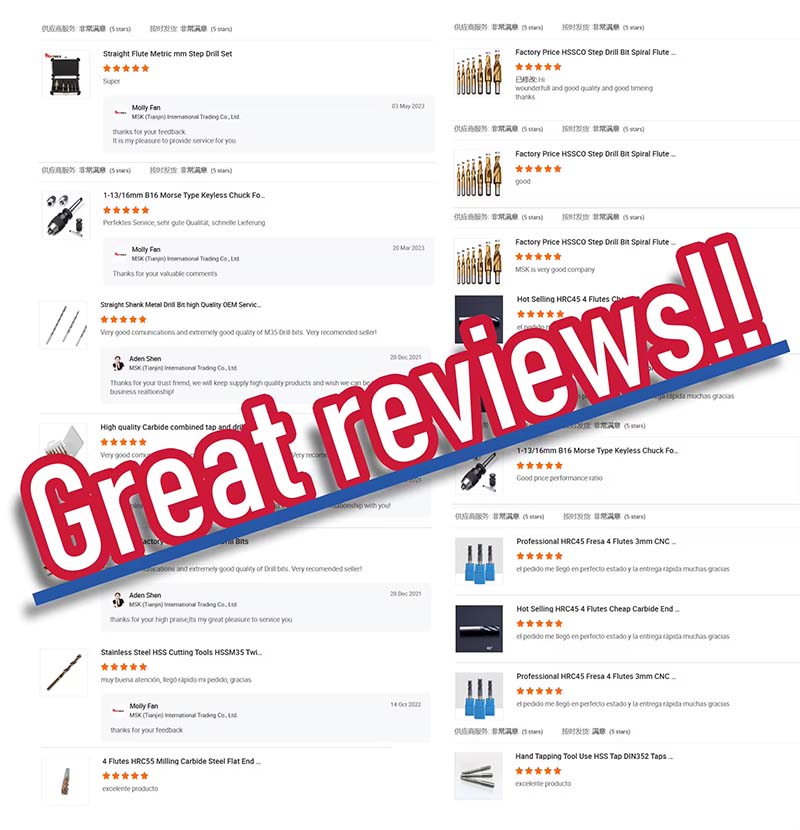

Why Choose Us

Factory Profile

About Us

FAQ

Q1: who are we?

A1: Founded in 2015, MSK (Tianjin) Cutting Technology CO.Ltd has grown continuously and passed Rheinland ISO 9001

authentication.With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end,professional and efficient CNC tool.

Q2: Are you trading company or manufacturer?

A2: We are the factory of carbide tools.

Q3: Can you send products to our Forwarder in China?

A3: Yes,if you have Forwarder in China,we will glad to send products to him/her.Q4: What terms of payment are acceptable?

A4: Normally we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, and we also provide label printing service.

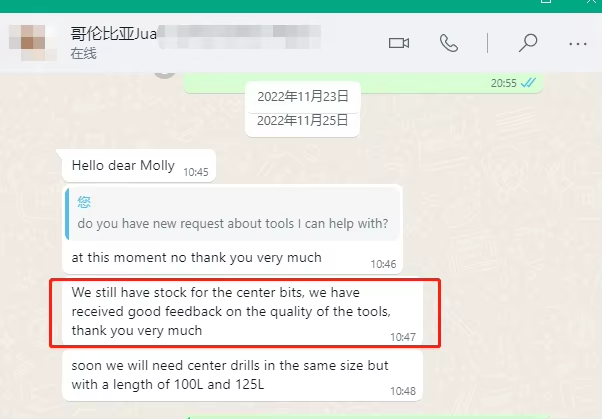

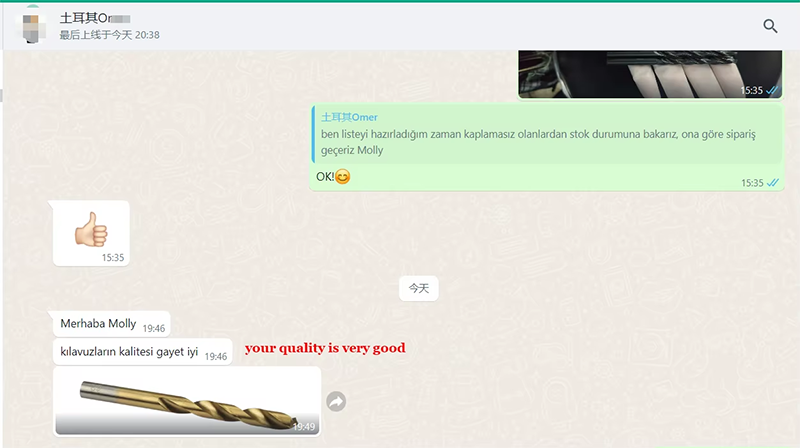

Q6: Why should you choose us?

A6:1) Cost control - purchasing high-quality products at an appropriate price.

2) Quick response - within 48 hours, professional personnel will provide you with a quote and address your concerns.

3) High quality - The company always proves with sincere intention that the products it provides are 100% high-quality.

4) After sales service and technical guidance - The company provides after-sales service and technical guidance according to customer requirements and needs.