Ma ka honua wikiwiki o ka hana uila, kahi e wehewehe ai ka micron-level precision i ka kūleʻa, ʻo ka hoʻokomo ʻana o Next-Gen PCB Board Drill Bits e hōʻailona ana i kahi lele nui i ka hana ʻana i ka papa kaapuni. Hoʻolālā ʻia no ka ʻeli ʻana, engraving, a me ka micromachining ma nā papa kaapuni i paʻi ʻia (PCB) a me nā substrates ultra-thin ʻē aʻe, ʻo kēia Tungsten Steel.Mīkini Drill PCBHoʻohui nā mea hana i nā mea aerospace-grade me ka ʻenehana paʻa seismic e wehewehe hou i ka pono a me ka lōʻihi o ka hana kiʻekiʻe.

ʻO ka maikaʻi o ka ʻenekinia: No ke aha he mea nui ka Tungsten Steel

Aia ma ka puʻuwai o kēia mau ʻāpana drill tungsten carbide (WC), kahi mea i koho ʻia no kāna hui ʻana o ka paʻakikī (HRA 92), ke kūpaʻa ʻaʻahu, a me ka pololei o ke kūkulu ʻana. 'A'ole e like me ka HSS ma'amau (High-Speed Steel) drills, keia hana kila tungsten e haawi:

ʻO 3X ʻOi aku ka lōʻihi o ke ola ʻana: kū i ka 15,000+ mau pōʻai wili ma nā papa fiberglass FR-4 me ka ʻole o ka hōʻino ʻia.

ʻO ka Micro-Grain Structure: Sub-0.5µm carbide grains e hōʻoiaʻiʻo i ka ʻoki ʻoki ʻana i nā ʻaoʻao, e loaʻa ana nā anawaena puka liʻiliʻi e like me 0.1mm me ± 0.005mm hoʻomanawanui.

Hoʻolālā Anti-Fracture: Hoʻoikaika ʻia ka geometry shank e pale i ka haki ʻana i ka wā o nā hana kiʻekiʻe-RPM (30,000–60,000), ʻoiai i loko o nā mea PCB i piha i ka ceramic.

ʻO ka hoʻāʻo ʻana o ka ʻaoʻao ʻekolu e ka Precision Machining Institute of Technology e hōʻoia i kēia mau bits e mālama i ka Ra 0.8µm i hoʻopau ʻia ma hope o 10,000 mau puka - he mea koʻikoʻi no ka hōʻailona hōʻailona kiʻekiʻe i nā polokalamu 5G a me IoT.

Paʻa Seismic: ʻOki ʻole me ka ʻae ʻole

Pono ka hoʻoheheʻe ʻana o PCB i ka paʻa paʻa e pale ai i ka "hele" a i ʻole ka hole misalignment. ʻO ka Proprietary Seismic Blade Edge Design e kamaʻilio i kēia ma o:

Asymmetric Flute Geometry: Hoʻohālikelike i ka haʻalele ʻana i ka chip a me ka haʻalulu haʻalulu, e hōʻemi ana i nā ikaika lateral e 40%.

Nano-Coated Helix Angle: ʻO kahi helix 30° me ka uhi TiAlN e hōʻemi i ka hoʻoulu ʻana o ka wela (<70 ° C) i ka wā e hana mau ai.

Nā Kūlana Anti-Resonance: Hoʻopau nā ʻano micro-channels laser-etched i nā alapine harmonic, e hōʻoia ana i ka pololei o ke kūlana i loko o 5µm ma waena o 10-layer PCBs.

I loko o kahi ho'āʻo koʻikoʻi e wili ana i nā lua 0.3mm ma o nā papa 2mm i uhi ʻia i ka aluminika, ua hōʻike kēia mau ʻāpana i ka ʻaʻe ʻole ma luna o 500 mau pōʻai holoʻokoʻa.

Nā noi ma nā ʻoihana āpau

Mea Hoʻohana Electronics

No nā mea hana motherboard smartphone:

0.2mm Micro-Vias: Loaʻa i ka 99.9% ka nui o nā hua ma nā papa HDI 12-layer.

20% ʻOi aku ka wikiwiki o ka hānai ʻana: Hoʻohana ʻia e ka hoʻohaʻahaʻa ʻana i ka friction a me ka hoʻopaʻa ʻana i ka chip.

Kaʻa uila

I ka hana ʻana o ka module mana EV:

Ma o-Hole Pono: Mālama ʻia 100% ka hoʻomau uila ma 1.6mm-mānoanoa thermal-conductive substrates.

ʻO ka hana ʻana i ka Coolant-Free: ʻAʻole hiki ke hoʻomaloʻo maloʻo i ka hoʻohaumia ʻana i nā ʻōnaehana hoʻokele pākaukau.

Aerospace & Palekana

ʻO ka ʻeli ʻana i nā lua 0.15mm i nā kaʻa kaʻa polimide flex:

Zero Delamination: ʻOiai i loko o 200°C kiʻekiʻe-humidity kaiapuni.

EMI Shield Patterning: ʻO ke kahakaha pololei ʻana no nā papa pale RF e pili ana i ka graphene.

ʻIkepili ʻenehana

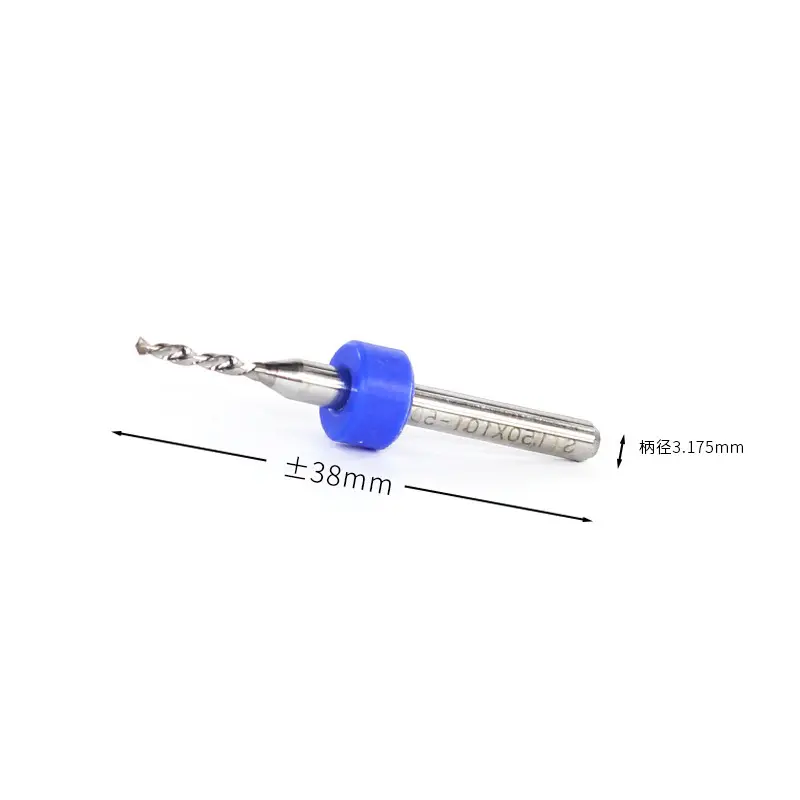

Ke Anawaena: 0.1mm–3.175mm (0.004"–1/8")

ʻAno Shank: 3.175mm maʻamau (1/8") a i ʻole ka hoʻohālikelike ER collet maʻamau

Nā Koho Pahu: TiN (gula), TiCN (uliuli), a i ʻole Diamond-Like Carbon (DLC)

RPM kiʻekiʻe: 80,000 (pili i ke anawaena)

Hoʻohālikelike: ʻO nā mīkini wili CNC, nā mīkini pahu PCB automated, nā mea hana wili lima

Hoʻoholo hou ʻia ke kumu kūʻai

Ua hōʻike ʻia kahi loiloi kumu kūʻai e kahi mea hana PCB Taiwanese:

$18,500 Hoʻokohu Makahiki: Hoʻemi ʻia nā pani pani drill bit (mai 12 a 4 sets/makahiki).

15% Hoʻemi ʻana i ka ikehu: ʻO nā koi torque spindle haʻahaʻa.

Zero Rework: Hoʻopau ʻia he $220k/makahiki ma nā papa i ʻoki ʻia mai ka drill wander.

Hoʻomau i kūkulu ʻia i loko

Hoʻopili hou ʻia: 100% biodegradable foam trays.

RoHS & REACH Compliance: Kaawale mai ke kēpau, cadmium, a me nā mea ʻino ʻē aʻe.

Ola Mea Hana Hoʻonui: 60% haʻahaʻa haʻahaʻa tungsten hoʻohana vs.

Nā Hōʻike Hoʻohana

"ʻO ka hoʻololi ʻana i kēia mau ʻāpana kila tungsten he mea hoʻololi," wahi a Hiroshi Tanaka, Luna Hoʻokele ma kahi mea hana sensor ma Kyoto. "Ke ʻeli nei mākou i 20,000 mau puka i kēlā me kēia neʻe me ka hoʻololi ʻole ʻana i nā mea hana - kahi mea hiki ʻole ke noʻonoʻo ʻia me kā mākou mau hana HSS kahiko. ʻO ka hoʻolālā seismic wale nō i ʻoki i kā mākou hole-position rejects e 95%.

No ke aha e koho ai i kēia mau PCB Board Drill Bits?

ʻAʻole hiki ke haʻihaʻi ʻia: No ka pololei like me ka laser i nā papa kiʻekiʻe kiʻekiʻe interconnect (HDI).

ʻO ka wikiwiki me ka ʻole o ka ʻālana: E wili i nā lua 0.3mm ma 400 mau puka/minuke me ka ʻole o ka hoʻopaʻapaʻa ʻana i ka maikaʻi o ka lihi.

Hoʻohālikelike Universal: Hana pū me FR-4, Rogers, aluminika, a me nā laminates i hoʻoikaika ʻia i ke aniani.

Hoʻolālā Hōʻike Hou: Mākaukau no nā mea PCB hou aʻe e like me ka halogen-free a me nā dielectrics ultra-low-loss.

Ka hopena

Ma kahi ʻoihana kahi e kuhikuhi ai kēlā me kēia micron i ka loaʻa kālā a me ka hana, ʻo kēia mau Tungsten SteelʻO nā ʻāpana wili papa PCBʻoi aku ma mua o nā mea hana - he mea hoʻolālā maikaʻi lākou. Ma ka hoʻohui ʻana i ka ʻepekema waiwai me ka ʻenehana kūpaʻa, hāʻawi lākou i nā mea hana e pana i nā palena o ka miniaturization i ka wā e ʻoki ana.

Ka manawa hoʻouna: Mar-21-2025