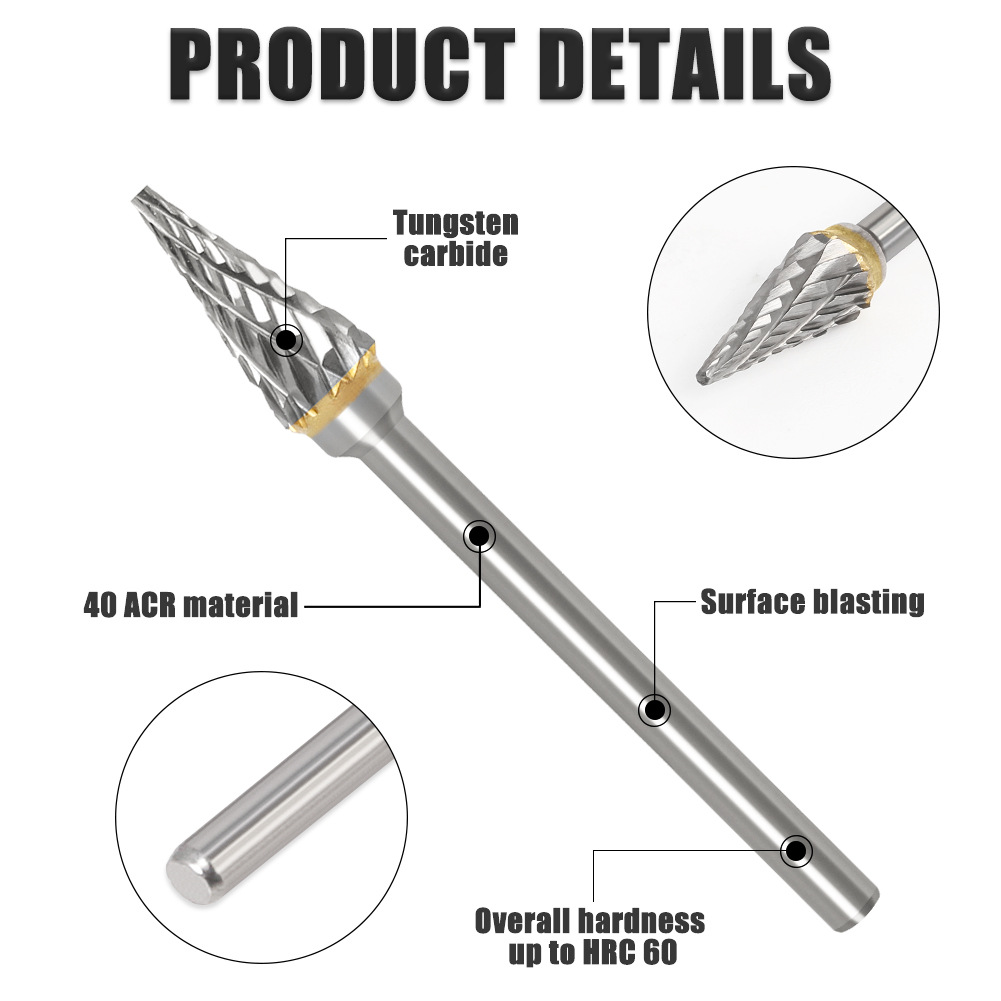

Tungsten Carbide Rotary Burrs Burr Bits Don Karfe

BAYANIN KYAUTATA

Ana amfani da fayilolin rotary na Carbide musamman don kayan aikin wuta ko kayan aikin huhu, kuma ana iya shigar da su akan kayan aikin injin.

FALALAR

Fayil mai jujjuyawar Carbide babban kayan aiki ne mai mahimmanci don masu dacewa da kayan aikin niƙa. Yana da halin maye gurbin ƙananan ƙafar niƙa tare da rike ba tare da gurɓataccen ƙura ba, rayuwar sabis ɗin daidai yake da ɗaruruwan ƙananan ƙafafun niƙa tare da rikewa, kuma aikin sarrafawa yana ƙaruwa fiye da sau 5. Abu ne mai sauƙin sarrafawa, mai sauƙin amfani, mai aminci kuma abin dogaro, yana rage nauyi aikin hannu da farashin samarwa.

Amfani: Fayilolin rotary na Carbide ana amfani da su sosai, kuma ana amfani da su wajen sarrafawa da kera kayan aikin abrasive. Injin gyare-gyare, zagaye da ramuka don ayyuka marasa kyau na inji, tsaftace gefuna na simintin gyare-gyare, gyare-gyare, da sassan walda; Ƙarshen bututu, masu gudu, da zane-zane da zane-zane na ƙarfe da kayan da ba na ƙarfe ba (kashi, Jade, dutse) .

SANARWA

1. Kafin aiki, da fatan za a karanta saurin aiki don zaɓar kewayon saurin da ya dace (da fatan za a koma ga yanayin saurin farawa da aka ba da shawarar). Ƙananan gudu zai shafi rayuwar samfur da ƙarewar ƙasa, yayin da ƙananan gudu zai shafi ƙaurawar guntu, magana ta inji da lalacewa na samfurin da bai kai ba.

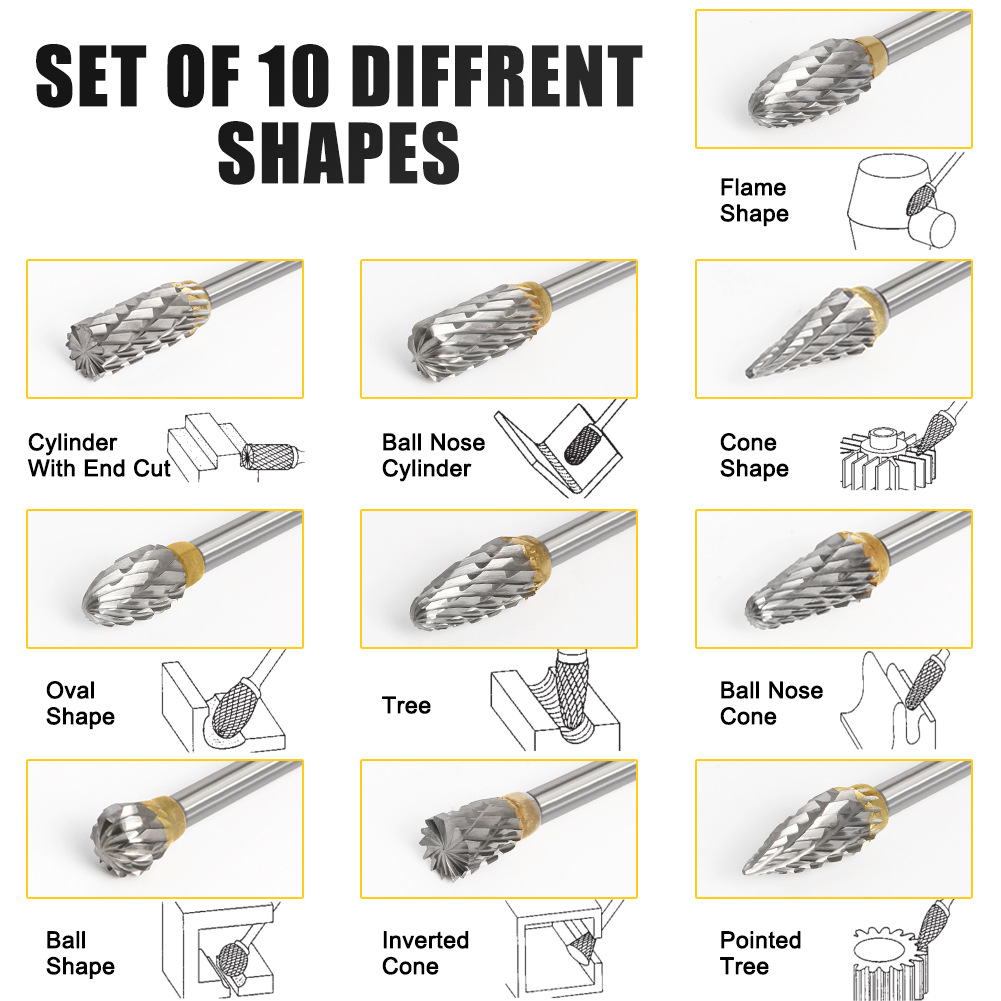

2. Zaɓi siffar da ta dace, diamita da bayanin haƙori don aiki daban-daban.

3. Zaɓi injin injin lantarki mai dacewa tare da aikin barga.

4. Tsawon ɓangaren da aka fallasa na hannun da aka ƙulla a cikin chuck shine mafi yawan 10mm. (Sai da hannun tsawo, gudun ya bambanta)

5. Idling kafin amfani da shi don tabbatar da mai kyau concentricity na Rotary fayil, eccentricity da vibration zai haifar da wanda bai kai ba lalacewa da workpiece lalacewa.

6. Ba shi da kyau a yi amfani da matsa lamba mai yawa yayin amfani. Matsi mai yawa zai rage rayuwa da ingancin kayan aiki.

7. Bincika cewa workpiece da lantarki grinder an clamped daidai da tam kafin amfani.

8. Sanya gilashin kariya masu dacewa lokacin amfani.