Tungsten Carbide Flow Drill Bit

BAYANIN KYAUTATA

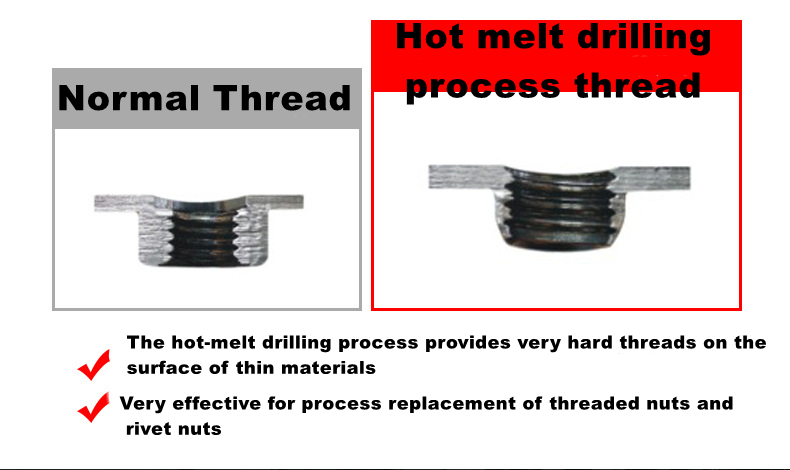

Ka'idar hakowa mai zafi

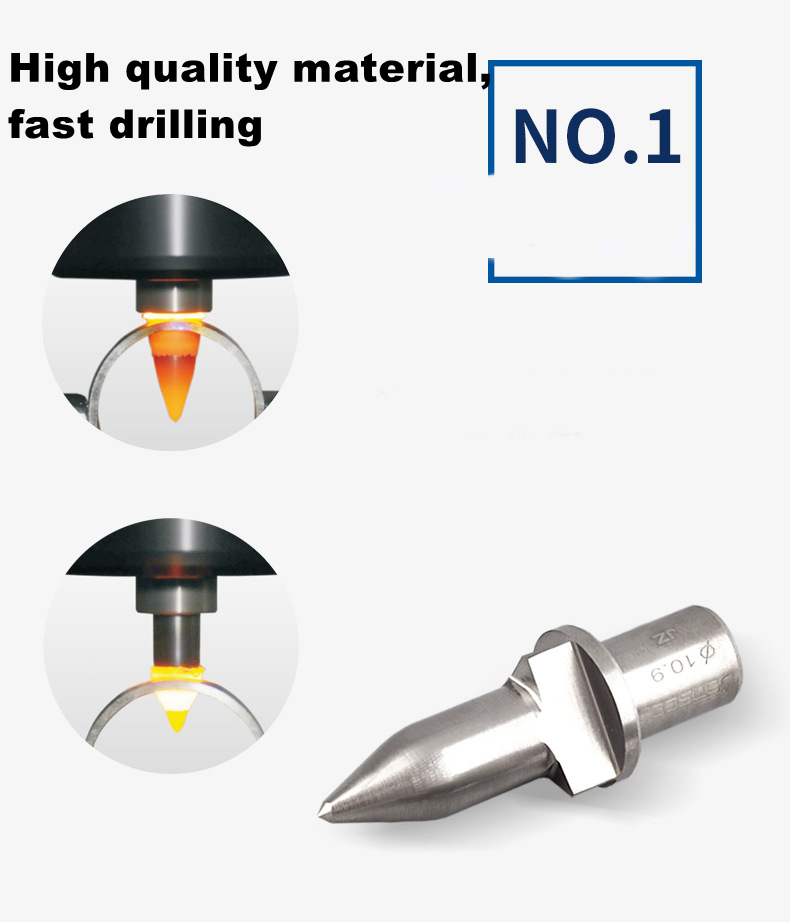

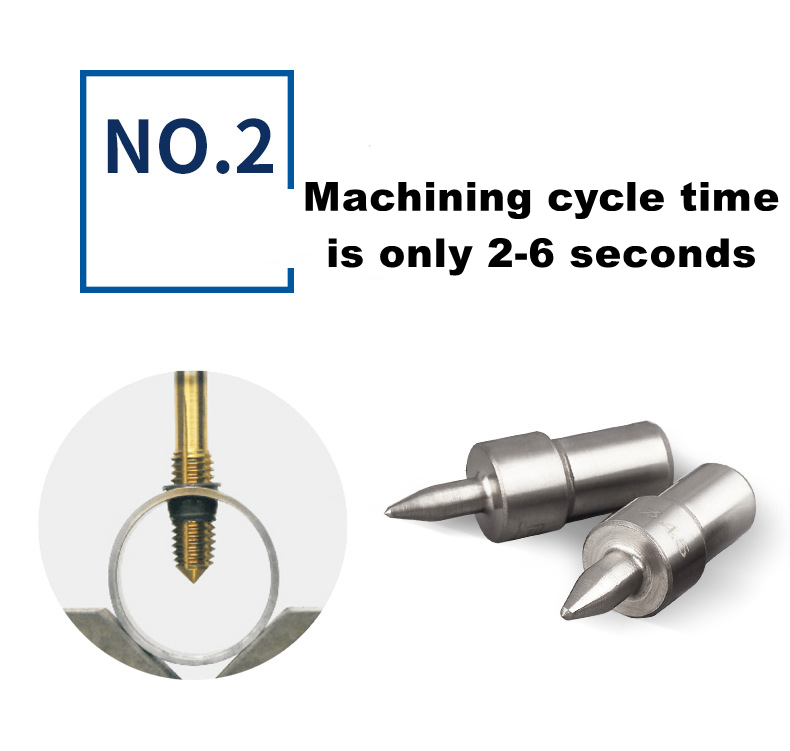

Ƙunƙarar zafi mai zafi yana haifar da zafi ta hanyar jujjuyawa mai sauri da juzu'i na axial don yin filastik da maye gurbin kayan. A lokaci guda kuma, yana naushi tare da samar da daji kamar kauri da yawa sau 3, sannan yana fitar da famfo ta hanyar famfo don yin shi akan siraran kayan. Madaidaicin madaidaici, zaren ƙarfi mai ƙarfi.

SHAWARAR AMFANI A CIKIN KWANAKI

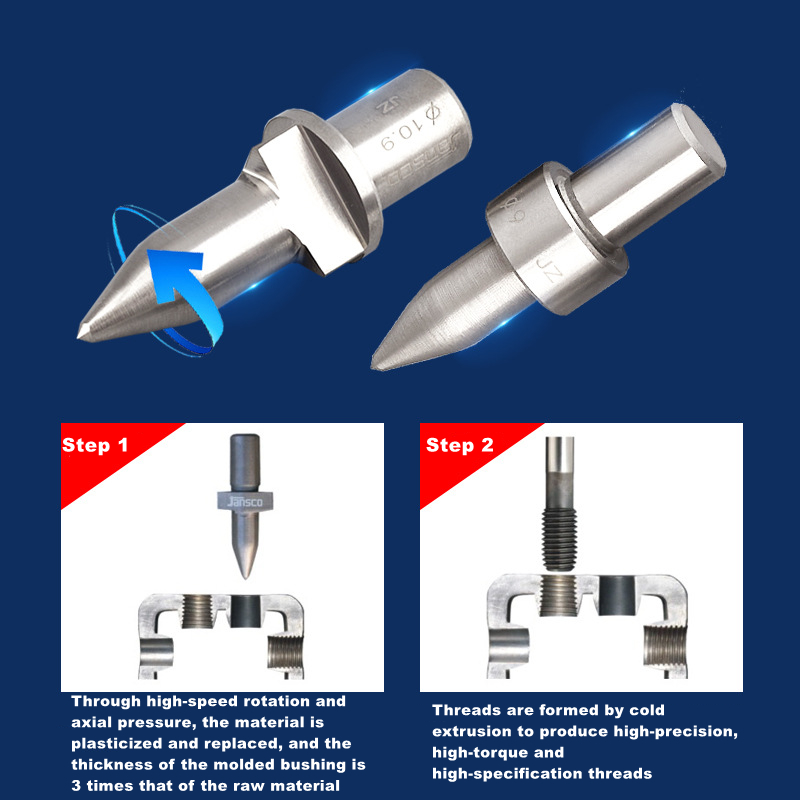

Mataki na farko: yin filastik abu ta hanyar juyawa mai sauri da matsa lamba axial. Kauri na gyare-gyaren daji ya ninka sau 3 na albarkatun kasa.

Mataki na biyu: An kafa zaren ta hanyar extrusion mai sanyi don samar da madaidaicin madaidaici, mai ƙarfi da ƙayyadaddun ƙayyadaddun bayanai.n zare

| Alamar | MSK | Tufafi | No |

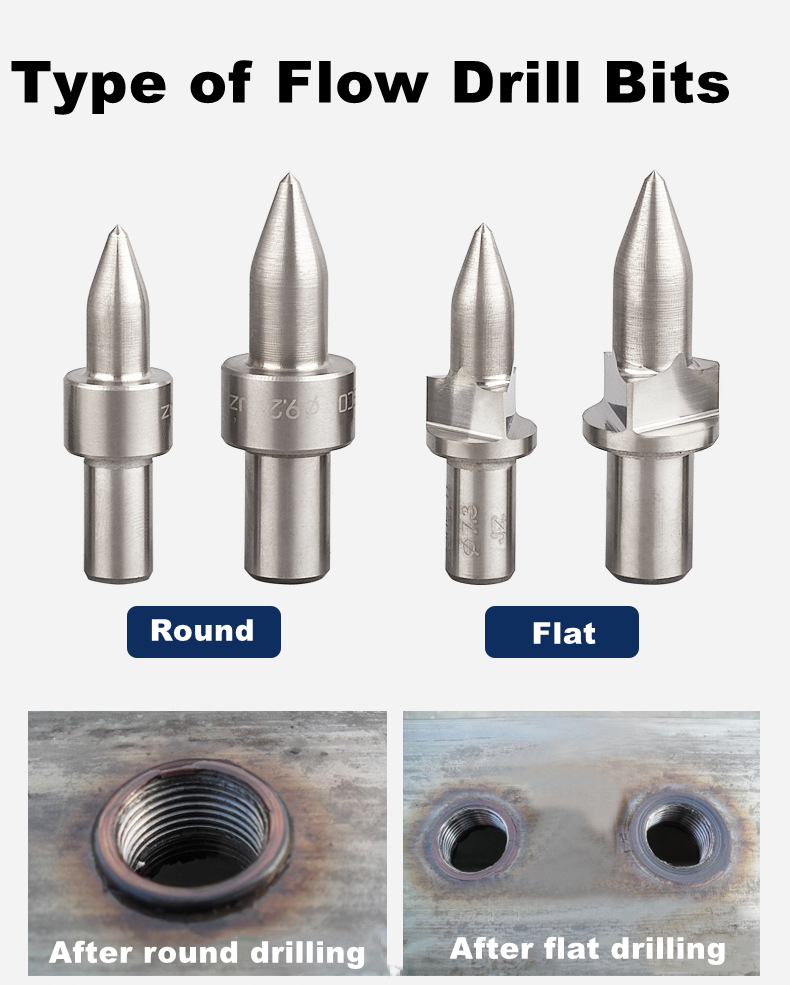

| Sunan samfur | Saitin Juyawar Zazzaɓi Mai zafi | Nau'in | Nau'in Lebur/Zagaye |

| Kayan abu | Carbide Tungsten | Amfani | Yin hakowa |

FALALAR

Kariya don amfani da narke mai zafi:

1. Workpiece abu: zafi-narke rawar soja ya dace da sarrafa daban-daban karfe kayan da diamita na 1.8-32mm da bango kauri na 0.8-4mm, irin su baƙin ƙarfe, m karfe, bakin karfe, titanium, aluminum, jan karfe, jan karfe, tagulla (Zn abun ciki kasa da 40%), aluminum gami (Si abun ciki kasa da 0.5%), da dai sauransu zafi rawar soja da lokacin farin ciki da kayan, da dai sauransu.

2. Narke mai zafi: Lokacin da zafi-narke yana aiki, ana haifar da babban zafin jiki fiye da digiri 600 nan take. Narke mai zafi na musamman zai iya tsawanta rayuwar sabis na rawar zafi mai zafi, inganta yanayin ciki na silinda, da kuma samar da siffar mai tsabta da gamsarwa. Ana bada shawara don ƙara ƙaramin adadin zafi mai zafi akan kayan aiki don kowane ramukan 2-5 da aka haƙa a cikin ƙarfe na yau da kullun; ga bakin karfe workpieces, ga kowane rami da aka haƙa, ƙara zafi narke manna da hannu; da kauri da wuya abu, mafi girma mita na ƙari.

3. Shank da chuck na zafi narke rawar jiki: Idan babu zafi na musamman, yi amfani da matsewar iska don kwantar da hankali.

4. Kayan aikin hakowa: idan dai nau'ikan hakowa daban-daban, injinan niƙa da cibiyoyin injina tare da saurin gudu da ƙarfi sun dace da hakowa mai zafi; Kauri daga cikin kayan da bambanci a cikin kayan da kansa duk suna shafar ƙaddarar saurin juyawa.

5. Ramin da aka riga aka kera: Ta hanyar hako ƙaramin rami mai farawa, ana iya guje wa nakasar aikin aiki. Ramin da aka riga aka kera na iya rage ƙarfin axial da tsayin silinda, kuma yana iya samar da gefuna mai faɗi a mafi ƙanƙan ƙarshen silinda don guje wa lanƙwasa nakasar bakin ciki mai bango (kasa da 1.5mm) workpieces.

6. Lokacin da ake bugawa, yi amfani da man fetur: ana bada shawarar yin amfani da famfo na extrusion, wanda ba a samuwa ta hanyar yanke ba amma ta hanyar extrusion, don haka suna da ƙarfin ƙarfi da ƙima. Hakanan yana yiwuwa a yi amfani da famfo yankan na yau da kullun, amma yana da sauƙin yanke silinda, kuma diamita na rawar zafi mai zafi ya bambanta kuma yana buƙatar yin shi daban.

7. Kula da rawar zafi mai zafi: Bayan an yi amfani da rawar narke mai zafi na ɗan lokaci, za a sawa saman, kuma a haɗa wasu ƙazanta masu zafi ko najasa kayan aiki a jikin mai yankan. Matsa rawar zafi mai zafi a kan guntun lathe ko injin niƙa, kuma a niƙa shi da man goge baki. Kada ku kula da aminci.