A matsayin kayan aiki na yau da kullun don sarrafa zaren ciki, ana iya raba famfo zuwa famfo mai karkace, famfo mai karkata zuwa gefe, famfo madaidaicin tsagi da famfo zaren bututu bisa ga sifofinsu, kuma ana iya raba su zuwa famfo na hannu da famfo na inji gwargwadon yanayin amfani. Rarraba zuwa awo, Amurka, da famfo na masarauta. Kun saba da su duka?

01 Matsa rarrabawa

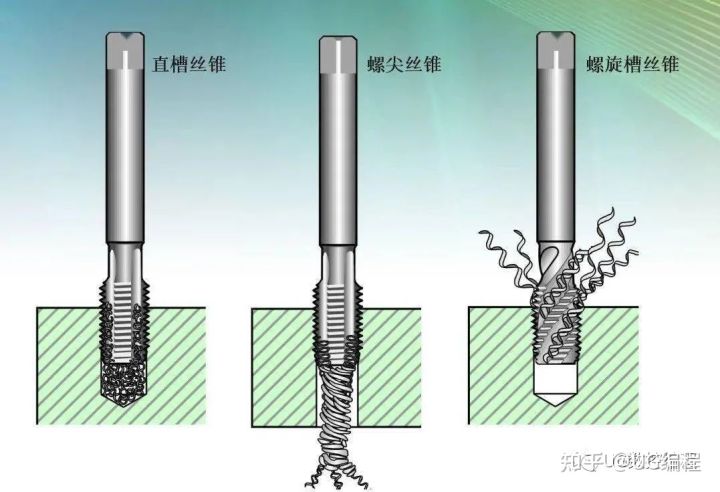

(1) Yankan famfo

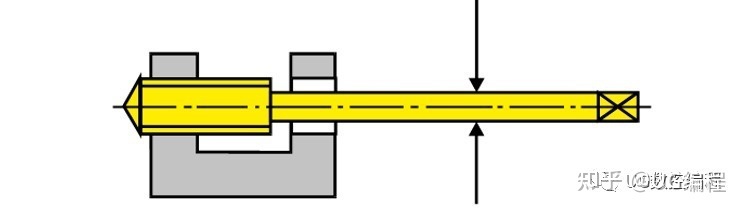

1) Matsa sarewa madaidaiciya: ana amfani da shi don sarrafa ta cikin ramuka da makafi, guntun ƙarfe yana wanzuwa a cikin ramin famfo, ingancin zaren da aka sarrafa ba shi da tsayi, kuma an fi amfani dashi don sarrafa gajerun kayan guntu, kamar baƙin ƙarfe mai launin toka, da sauransu.

2) Karkataccen tsagi famfo: ana amfani da shi don sarrafa rami na makafi tare da zurfin rami ƙasa da ko daidai da 3D, ana fitar da filayen ƙarfe tare da tsagi mai karkace, kuma ingancin saman zaren yana da girma.

10 ~ 20 ° helix kwana famfo iya aiwatar da zaren zurfin kasa da ko daidai da 2D;

28 ~ 40 ° helix kwana famfo iya aiwatar da zaren zurfin kasa da ko daidai da 3D;

Matsa kusurwar helix na 50° na iya aiwatar da zurfin zaren ƙasa da ko daidai da 3.5D (yanayin aiki na musamman 4D).

A wasu lokuta (kayan wuya, babban farati, da sauransu), don samun ingantacciyar ƙarfin haƙori, ana amfani da bututun sarewa don yin inji ta ramuka.

3) Karkace maki famfo: yawanci kawai ana amfani da shi ta hanyar ramuka, girman diamita na tsawon tsayi zai iya kaiwa 3D ~ 3.5D, ana fitar da kwakwalwan ƙarfe a ƙasa, ƙananan ƙananan ƙananan ƙananan ƙananan ƙananan ƙananan ƙananan, kuma ingancin farfajiya na zaren da aka yi amfani da shi yana da girma, wanda kuma aka sani da gefen kusurwa ta famfo ko koli tap.

Lokacin yankan, wajibi ne a tabbatar da cewa an shigar da duk sassan yankan, in ba haka ba za a sami tsinkewar haƙori.

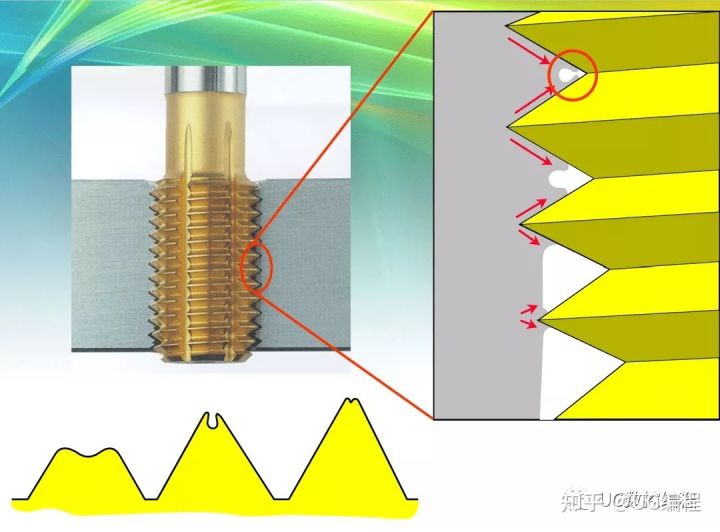

(2) Fitar famfo

Ana iya amfani da shi don sarrafa ta ta ramuka da ramukan makafi, kuma siffar haƙori yana samuwa ne ta hanyar nakasar filastik na kayan, wanda za'a iya amfani dashi kawai don sarrafa kayan filastik.

Babban fasalinsa:

1) Yi amfani da nakasar filastik na aikin aikin don aiwatar da zaren;

2) Yankin giciye na famfo yana da girma, ƙarfin yana da girma, kuma ba shi da sauƙin karya;

3) Gudun yankan na iya zama mafi girma fiye da na yankan famfo, kuma ana ƙara yawan aiki daidai da haka;

4) Saboda tsarin extrusion mai sanyi, kayan aikin injiniya na kayan aikin da aka sarrafa sun inganta, haɓakar daɗaɗɗa yana da girma, da ƙarfin zaren, juriya da juriya na lalata suna inganta;

5) Injin guntu.

Kasawarta su ne:

1) za a iya amfani da shi kawai don sarrafa kayan filastik;

2) Farashin masana'anta yana da yawa.

Akwai nau'ikan tsari guda biyu:

1) Fitar famfo ba tare da tsagi na man fetur ba ana amfani da su ne kawai don yin injin ramukan makafi;

2) Taffun cirewa tare da raƙuman mai sun dace da duk yanayin aiki, amma yawanci ƙananan bututun diamita ba sa tsara tsaunukan mai saboda matsalolin masana'antu.

(1) Girma

1) Tsawon gabaɗaya: Kula da wasu yanayin aiki waɗanda ke buƙatar tsayi na musamman

2) Tsawon rami: wuce sama

3) Shank: A halin yanzu, ka'idodin shank na yau da kullun sune DIN (371/374/376), ANSI, JIS, ISO, da sauransu.

(2) Bangaren zare

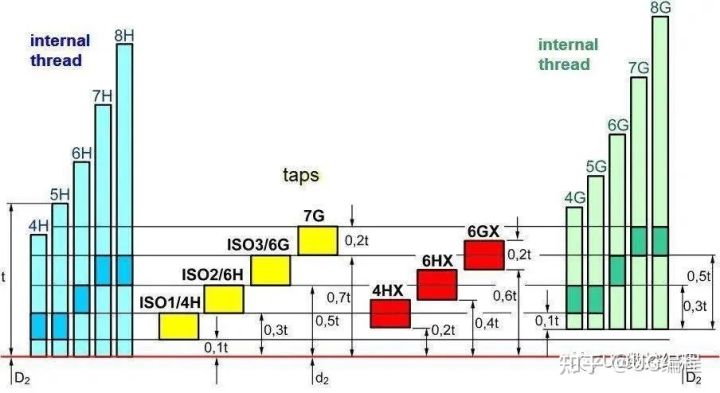

1) Daidaito: An zaɓi shi ta takamaiman ma'aunin zaren. Madaidaicin zaren ISO1/2/3 matakin daidai yake da matakin H1/2/3 na ƙasa, amma wajibi ne a kula da ƙa'idodin sarrafa cikin gida na masana'anta.

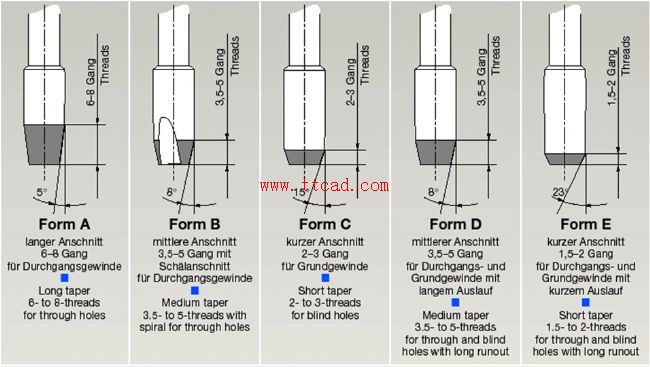

2) Yanke famfo: Yanke ɓangaren fam ɗin ya samar da wani ɓangare na ƙayyadaddun tsari. Gabaɗaya, tsawon lokacin yankan famfo, mafi kyawun rayuwar fam ɗin.

3) Gyaran haƙoran: Yana taka rawar taimako da gyara, musamman a yanayin rashin kwanciyar hankali na tsarin bugun, ƙarin haƙoran gyare-gyare, mafi girman juriya na bugawa.

(3) Yanke sarewa

1. Nau'in tsagi: Yana shafar ƙirƙira da fitar da filayen ƙarfe, wanda galibi sirri ne na kowane masana'anta.

2. Rake kusurwa da kusurwa: lokacin da aka ƙara famfo, famfo ya zama mai kaifi, wanda zai iya rage girman juriya, amma ƙarfi da kwanciyar hankali na haƙori yana raguwa, kuma kusurwar taimako shine kusurwar taimako.

3. Yawan ragi: yawan raguwa yana ƙaruwa kuma adadin yankan ya karu, wanda zai iya inganta rayuwar famfo yadda ya kamata; amma zai damfara guntu kau sarari, wanda ba shi da kyau ga guntu kau.

03 Matsa abu da sutura

(1) Kayan famfo

1) Karfe na kayan aiki: An fi amfani da shi don famfo incisor na hannu, wanda ba a saba gani ba a halin yanzu.

2) Karfe mai sauri mara-kyau: A halin yanzu, ana amfani da shi sosai azaman kayan famfo, kamar M2 (W6Mo5Cr4V2, 6542), M3, da sauransu, kuma lambar alama ita ce HSS.

3) Cobalt-dauke da high-gudun karfe: a halin yanzu amfani da ko'ina azaman famfo kayan, kamar M35, M42, da dai sauransu, da alama code ne HSS-E.

4) Foda karfe high-gudun karfe: An yi amfani dashi azaman babban kayan aikin famfo, aikin yana inganta sosai idan aka kwatanta da na sama biyu. Hanyoyin suna na kowane masana'anta kuma sun bambanta, kuma lambar yin alama ita ce HSS-E-PM.

5) Abubuwan carbide da aka yi da siminti: yawanci suna amfani da barbashi masu kyau da kyaututtuka masu kyau, waɗanda galibi ana amfani da su don kera bututun sarewa madaidaiciya don aiwatar da gajerun kayan guntu, kamar baƙin ƙarfe mai launin toka, babban silicon aluminum, da sauransu.

Taps suna dogara sosai akan kayan aiki, kuma zaɓin kayan aiki masu kyau na iya ƙara haɓaka sigogin tsarin na famfo, sa su dace da inganci da yanayin aiki mai ƙarfi, kuma a lokaci guda suna da rayuwar sabis mafi girma. A halin yanzu, manyan masana'antun famfo suna da nasu masana'antun kayan aiki ko tsarin kayan aiki. A sa'i daya kuma, saboda matsalolin albarkatun cobalt da farashin, an samu sabbin karafa masu saurin aiki da sauri marasa inganci.

(2) Rufin famfo

1) Tushen oxidation: Ana sanya fam ɗin a cikin tururin ruwa mai zafi don samar da fim ɗin oxide a saman, wanda ke da kyakkyawar tallatawa ga mai sanyaya, yana iya rage juzu'i, da hana famfo da kayan da za a yanke. Dace da machining m karfe.

2) Jiyya na Nitriding: Ana yin nitrided saman famfo don samar da wani yanki mai tauri, wanda ya dace da machining simintin ƙarfe, jefa aluminum da sauran kayan da ke da babban kayan aiki.

3) Steam + Nitriding: Haɗa fa'idodin waɗannan biyun na sama.

4) TiN: launi mai launin rawaya na zinari, tare da tauri mai kyau da lubricity, da mannewa mai kyau, wanda ya dace da sarrafa yawancin kayan.

5) TiCN: shafi mai launin shuɗi-launin toka tare da taurin kusan 3000HV da juriya mai zafi na 400 ° C.

6) TiN + TiCN: rufin rawaya mai duhu, tare da ingantaccen tauri da lubricity, dace da sarrafa yawancin kayan.

7) TiAlN: shuɗi-launin toka shafi, taurin 3300HV, zafi juriya har zuwa 900 ° C, za a iya amfani da high-gudun machining.

8) CrN: azurfa-launin toka shafi, m lubricating yi, yafi amfani ga sarrafa wadanda ba ferrous karafa.

Tasirin murfin famfo a kan aikin famfo yana da kyau a fili, amma a halin yanzu, yawancin masana'antun da masu sana'a suna aiki tare da juna don nazarin sutura na musamman.

04 Abubuwan da ke Shafar Taɓa

(1) Kayan aiki na bugawa

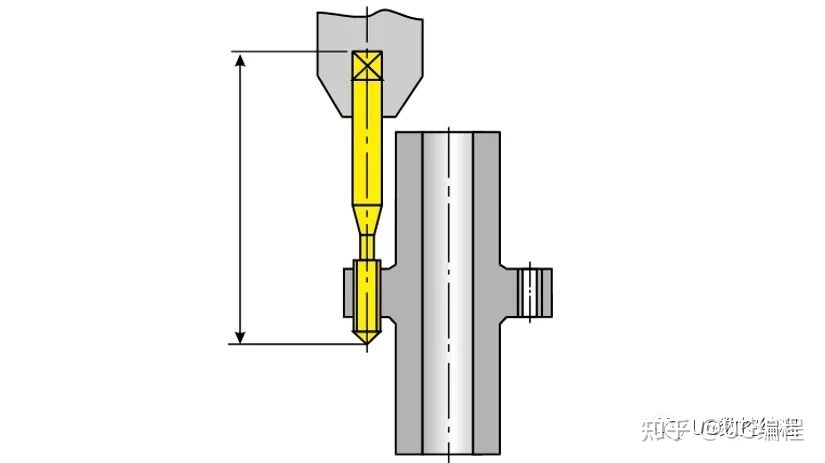

1) Kayan aiki na na'ura: Ana iya raba shi zuwa hanyoyin sarrafawa a tsaye da kuma a kwance. Don bugawa, aiki a tsaye ya fi aiki a kwance. Lokacin da aka yi sanyi na waje a cikin aiki a kwance, yana da muhimmanci a yi la'akari da ko sanyaya ya isa.

2) mariƙin buga kayan aiki: Ana ba da shawarar yin amfani da kayan aiki na musamman don taɓawa. Kayan aikin injin yana da ƙarfi kuma yana da ƙarfi, kuma an fi son mariƙin kayan aiki tare. Akasin haka, mai ɗaukar kayan aiki mai sassauƙa tare da ramuwa axial / radial yakamata a yi amfani da shi gwargwadon yiwuwa. . Sai dai ƙananan famfo diamita (

(2) Kayan aiki

1) Kayan aiki da taurin kayan aiki: taurin kayan aikin yakamata ya zama iri ɗaya, kuma gabaɗaya ba a ba da shawarar yin amfani da famfo don aiwatar da kayan aikin da suka wuce HRC42 ba.

2) Tapping ramin ƙasa: tsarin ramin ƙasa, zaɓi ɗigon rawar da ya dace; daidaiton girman rami na kasa; kasa rami rami bango ingancin.

(3) Matsalolin sarrafawa

1) Gudun juyawa: Tushen saurin jujjuyawar da aka bayar shine nau'in famfo, kayan aiki, kayan da za'a sarrafa da taurin, ingancin kayan aikin bugun, da sauransu.

Yawancin lokaci ana zaɓa bisa ga sigogin da mai yin famfo ya bayar, dole ne a rage saurin a ƙarƙashin yanayi masu zuwa:

- rashin ƙarfi na inji; babban famfo gudu; rashin isasshen sanyaya;

- kayan da ba su da daidaituwa ko taurin kai a cikin wurin taɗawa, kamar kayan haɗin gwal;

- an tsawaita famfo, ko kuma a yi amfani da sandar tsawo;

- Recumbent ƙari, sanyaya waje;

- Aiki na hannu, kamar rawar benci, rawar radial, da sauransu;

2) Ciyarwa: m tapping, ciyar = 1 zaren farar / juyin juya hali.

A cikin yanayin taɓawa mai sassauƙa da isassun masu canjin shank diyya:

Ciyarwa = (0.95-0.98) filaye/rev.

05 Nasihu don zaɓin famfo

(1) Hakuri na famfo na ma'auni daban-daban

Tushen Zaɓi: Ba za a iya zaɓar ƙimar ƙimar fam ɗin ba kuma a ƙayyade kawai bisa ga daidaiton zaren da ake sarrafa shi.

1) Kayan aiki da taurin aikin da za a sarrafa;

2) Kayan aiki na taɓawa (kamar yanayin kayan aikin injin, masu riƙe kayan aiki, zoben sanyaya, da sauransu);

3) daidaito da kuskuren masana'anta na famfo kanta.

Misali, lokacin sarrafa zaren 6H, lokacin sarrafa sassan karfe, ana iya amfani da madaidaicin famfo na 6H; lokacin sarrafa baƙin ƙarfe simintin launin toka, saboda tsakiyar diamita na famfo yana sawa da sauri kuma fadada ramukan dunƙule ƙananan ƙananan ne, yana da kyau a yi amfani da madaidaicin famfo na 6HX. Matsa, rayuwa za ta yi kyau.

Bayanan kula akan daidaiton famfo na Japan:

1) Yanke famfo OSG yana amfani da daidaitaccen tsarin OH, wanda ya bambanta da daidaitattun ISO. Tsarin daidaitaccen tsarin OH yana tilasta faɗin duka band ɗin haƙuri don farawa daga mafi ƙasƙanci mafi ƙasƙanci, kuma kowane 0.02mm ana amfani dashi azaman madaidaicin maki, mai suna OH1, OH2, OH3, da sauransu;

2) The extrusion famfo OSG yana amfani da daidaitaccen tsarin RH. Tsarin daidaitaccen tsarin RH yana tilasta faɗin duka band ɗin haƙuri don farawa daga ƙananan iyaka, kuma kowane 0.0127mm ana amfani dashi azaman matakin daidaito, mai suna RH1, RH2, RH3, da sauransu.

Don haka, lokacin amfani da famfo madaidaicin ISO don maye gurbin madaidaicin famfo na OH, ba za a iya la'akari da cewa 6H kusan daidai yake da maki OH3 ko OH4 ba. Yana buƙatar ƙaddara ta hanyar juyawa, ko kuma bisa ga ainihin yanayin abokin ciniki.

(2) Girman famfo

1) Wadanda aka fi amfani dasu sune DIN, ANSI, ISO, JIS, da dai sauransu;

2) An ba da izini don zaɓar tsayin da ya dace gabaɗaya, tsayin ruwa da girman shank bisa ga buƙatun aiki daban-daban na abokan ciniki ko yanayin da ake ciki;

3) Tsangwama yayin aiki;

(3) Abubuwa na asali guda 6 don zaɓin famfo

1) Nau'in zaren sarrafawa, metric, inch, Amurka, da sauransu;

2) Nau'in ramin ƙasa mai zaren, ta rami ko makaho;

3) Kayan aiki da taurin aikin da za a sarrafa;

4) Zurfin cikakken zaren aikin aiki da zurfin rami na kasa;

5) Daidaiton da ake buƙata na zaren aikin aiki;

6) Matsayin siffar famfo

Lokacin aikawa: Yuli-20-2022