A duniyar kayan lantarki, allon da aka buga (PCBs) sune kashin bayan kusan kowace na'ura da muke amfani da ita a yau. Daga wayoyin hannu zuwa na'urorin gida, PCBs suna da mahimmanci don haɗa nau'ikan abubuwan lantarki da yawa. Daya daga cikin mafi muhimmanci al'amurran da PCB masana'antu ne da hakowa tsari, wanda shi ne indabugu na kewaya allon rawar jikizo cikin wasa. A cikin wannan rukunin yanar gizon, za mu bincika nau'ikan nau'ikan raƙuman ruwa da ake amfani da su don PCBs, ƙayyadaddun su, da shawarwari don zaɓar kayan aikin da ya dace don aikinku.

Fahimtar PCB Drill Bits

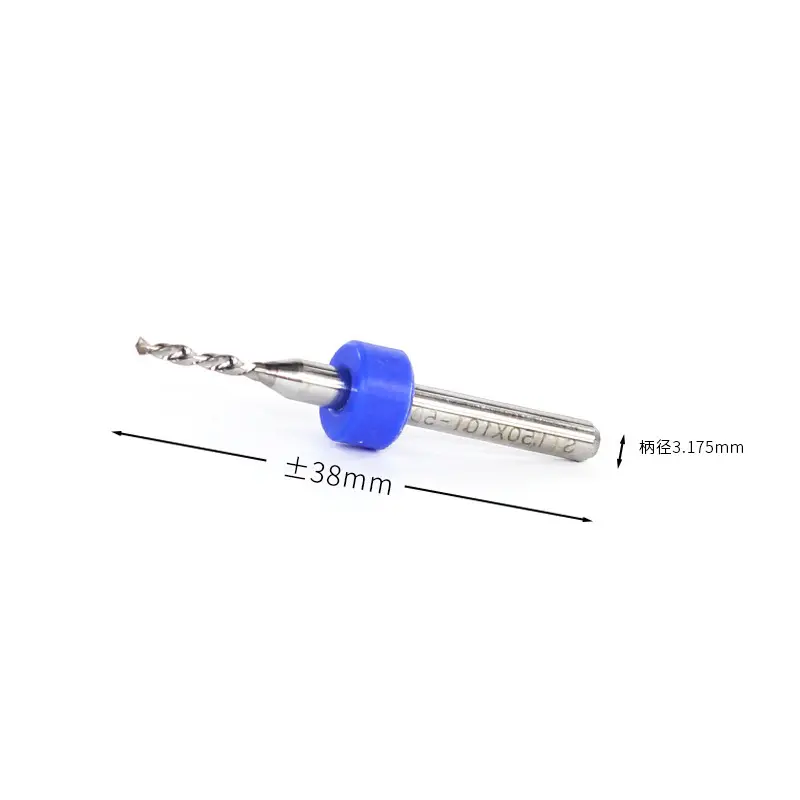

Fitar da bugu na bugu na katako kayan aiki ne na musamman da ake amfani da su don haƙa ramuka a cikin PCB don sanya abubuwan haɗin gwiwa da yin haɗin lantarki. Waɗannan ɓangarorin rawar soja sun zo da girma da kayayyaki iri-iri, kowanne an keɓe shi don takamaiman aikace-aikace. Daidaito da ingancin ɗigon rawar soja kai tsaye yana shafar aikin gabaɗaya da amincin PCB.

PCB Drill Bit Types

1. Twist Drill Bit:Wannan shine mafi yawan nau'in rawar sojan da ake amfani da su don PCBs. Suna da ƙirar karkace wanda ke taimakawa wajen cire tarkace yayin hakowa. Twist drill bits suna zuwa cikin diamita iri-iri don girman ramuka daban-daban.

2. Micro Drill Bits:Ƙananan ramuka masu mahimmanci suna da mahimmanci don aikace-aikacen da ke buƙatar ƙananan ramuka. Waɗannan ramukan rawar soja na iya haƙo ramuka ƙanana kamar 0.1 mm, yana sa su dace don PCB masu girma inda sarari ya iyakance.

3. Karbide Drill Bits:An yi su daga tungsten carbide, waɗannan raƙuman raƙuman ruwa an san su da tsayin daka da iya zama mai kaifi na dogon lokaci. Suna da tasiri musamman don hakowa ta kayan aiki masu wuya, suna mai da su mashahurin zaɓi don PCBs masu yawa.

4. Gishiri Mai Rufe Lu'u-lu'u:Don madaidaici da tsawon rai, lu'u-lu'u masu lu'u-lu'u masu lu'u-lu'u sune ma'auni na zinariya. Rufin lu'u-lu'u yana rage juzu'i da zafi don yanke tsafta da tsawon rayuwar kayan aiki. Ana amfani da waɗannan ɓangarorin rawar soja a cikin manyan aikace-aikace inda daidaito ke da mahimmanci.

Mabuɗin bayanai don la'akari

Lokacin zabar ɗigon bugu don allon da'ira, akwai wasu ƙayyadaddun bayanai da ya kamata ku yi la'akari:

- Diamita:Girman rawar rawar soja yana da mahimmanci don tabbatar da ramin ya hadu da ƙayyadaddun ƙira na PCB. Na kowa diamita jeri daga 0.2mm zuwa 3.2mm.

- Tsawon:Tsawon rawar rawar soja yakamata yayi daidai da kaurin PCB. Alkalan multilayer na iya buƙatar ɗan guntu mai tsayi.

- Kuskure masu kaifi:Kusurwoyi masu kaifi suna shafar ingancin yankan da ingancin rami. Madaidaitan kusurwoyi masu kaifi yawanci digiri 118 ne, amma ana iya amfani da kusurwoyi na musamman don takamaiman aikace-aikace.

- Abu:Kayan kayan aikin motsa jiki yana rinjayar aikinsa da tsawon rayuwarsa. Carbide da lu'u-lu'u masu lu'u-lu'u an fi so don dorewarsu.

Nasihu don zabar madaidaicin rawar rawar soja

1. Kimanta bukatun aikinku:Kafin siyan rawar motsa jiki, kimanta ƙayyadaddun ƙirar PCB ɗin ku. Yi la'akari da girman ramin, adadin yadudduka, da kayan da aka yi amfani da su.

2. Inganci fiye da farashi:Duk da yake yana iya zama abin sha'awa don zaɓar wani ɗan rahusa mai rahusa, saka hannun jari a cikin ƙaramin rawar gani mai inganci na iya ceton ku lokaci da kuɗi a cikin dogon lokaci. Ƙirar ƙira ta ƙima tana rage haɗarin karyewa kuma tabbatar da rami mai tsabta.

3. Gwaji Daban-daban iri:Idan ba ku da tabbacin abin da ya fi dacewa don aikin ku, yi la'akari da gwada wasu nau'o'in rawar soja daban-daban. Wannan zai taimake ka ka tantance wane bit drill ya fi dacewa don takamaiman aikace-aikacenka.

4. Kiyaye Kayan Aikinka:Kula da ɗimbin ƙwanƙwasa da kyau yana da mahimmanci don tsawaita rayuwarsu. Tsaftace da duba ɗigon rawar jiki akai-akai don lalacewa kuma maye gurbin ragowa kamar yadda ake buƙata don kiyaye kyakkyawan aiki.

A karshe

Fitar da bugu da aka buga da'ira rawar soja wani muhimmin bangaren na PCB masana'antu da kuma taka muhimmiyar rawa wajen tabbatar da daidaito da aminci. Ta hanyar fahimtar nau'ikan nau'ikan ramuka daban-daban da ke akwai da kuma yin la'akari da takamaiman ƙayyadaddun bayanai, zaku iya yanke shawarar da za ta inganta ingancin ayyukan ku na lantarki. Ko kai mai sha'awar sha'awa ne ko ƙwararren injiniya, saka hannun jari a cikin kayan aikin da suka dace zai haifar da kyakkyawan sakamako da ingantaccen aiki.

Lokacin aikawa: Fabrairu-20-2025