Lokacin zayyana da kera kwalayen da'ira (PCBs), daidaito shine maɓalli. Ɗaya daga cikin mahimman abubuwan da ke cikin tsarin kera na PCB shine ɗigon ramuka da ake amfani da shi don haƙa ramuka don abubuwan da aka haɗa da ganowa. A cikin wannan jagorar, za mu bincika nau'ikan nau'ikan nau'ikanPC Board drills, aikace-aikacen su, da kuma yadda za ku zaɓi madaidaicin rawar rawar aiki don aikinku.

Koyi game da raƙuman katako na PC

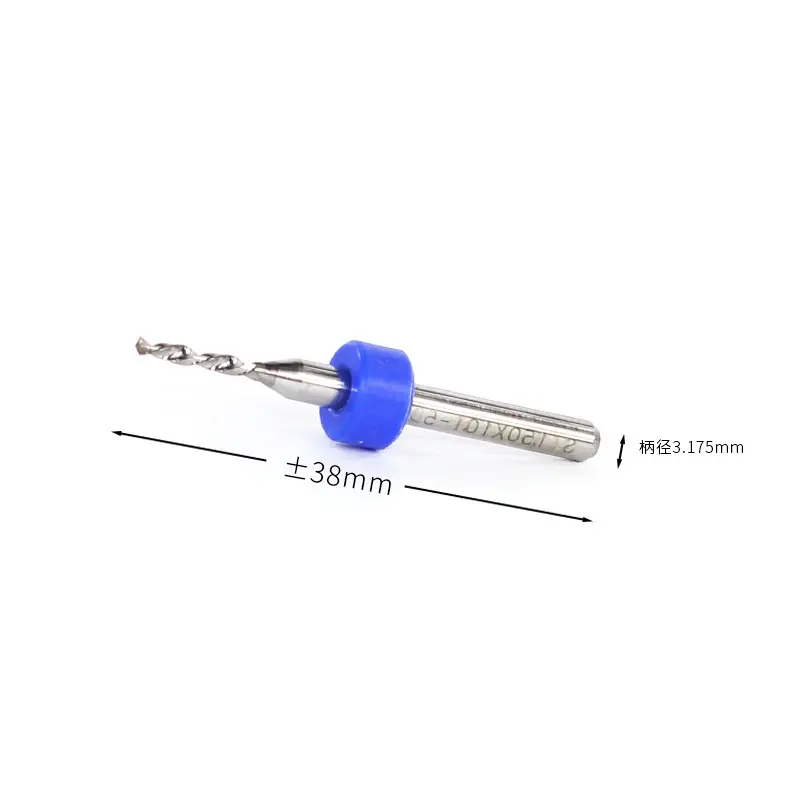

A PCB drill bit kayan aiki ne da aka ƙera musamman don haƙa ramuka a cikin PCBs. An ƙera waɗannan raƙuman rawar soja don ɗaukar kayan musamman da kauri na PCBs, waɗanda galibi sun haɗa da fiberglass, epoxy, da sauran kayan haɗin gwiwa. Matsakaicin rawar da ya dace na iya yin tasiri sosai ga ingancin PCB ɗin ku, yana shafar komai daga amincin haɗin gwiwar ku zuwa gabaɗayan aikin na'urar ku ta lantarki.

Nau'o'in Bugawar Hukumar Zazzagewar Wuta

1. Twist drill bit: Wannan shine mafi yawan nau'in juzu'i da ake amfani da su don PCBs. Suna nuna ƙirar tsagi mai karkace wanda ke taimakawa share tarkace yayin hakowa. Twist drill bits suna da yawa kuma ana iya amfani da su a cikin nau'ikan ramuka iri-iri, yana mai da su mashahurin zaɓi tsakanin masu son da ƙwararru iri ɗaya.

2. Micro Drills: Don aikace-aikacen da ke buƙatar ƙananan ramuka, ƙananan ramuka suna da mahimmanci. Waɗannan ramukan rawar soja na iya haƙo ramuka ƙanana kamar 0.1 mm, yana sa su dace don PCB masu girma inda sarari ya iyakance. Koyaya, suna buƙatar kulawa da hankali da ingantattun dabarun hakowa don guje wa karye.

3. Carbide Drill Bits: An yi shi da tungsten carbide, waɗannan raƙuman ruwa an san su da tsayin daka da iya zama mai kaifi na dogon lokaci. Suna da tasiri musamman don hakowa ta kayan aiki masu wahala kuma galibi ana amfani da su a cikin ƙwararrun masana'antar PCB.

4. Lu'u-lu'u Mai Rufaffen Drill Bits: Don daidaito na ƙarshe da tsawon rai, lu'u-lu'u masu lu'u-lu'u mai kyau zabi ne mai kyau. Rufin lu'u-lu'u yana sa hakowa ya fi sauƙi kuma yana rage haɗarin guntu ko fashe kayan PCB. Waɗannan ɓangarorin rawar soja gabaɗaya sun fi tsada, amma don ingantattun ayyuka, sun cancanci saka hannun jari.

Zabi madaidaicin abin toshewa

Lokacin zabar madaidaicin bututun jirgi na PC don aikinku, la'akari da waɗannan abubuwan:

- Material: Nau'in kayan da aka yi amfani da su don PCB zai shafi zaɓin rawar soja. Don daidaitattun allunan kewayawa na FR-4, juzu'i mai jujjuyawa ko ramin carbide yakan isa. Don ƙarin kayan aiki na musamman, kamar yumbu ko PCBs na ƙarfe-ƙarfe, ana iya buƙatar ɗan lu'u-lu'u mai lu'u-lu'u.

- Girman Ramin: Ƙayyade girman ramin da ake buƙatar haƙawa. Idan ƙirar ku ta ƙunshi duka daidaitattun ramuka da ƙananan ramuka, kuna iya saka hannun jari a cikin muryoyin murɗawa da ƙananan ramuka.

- Dabarun hakowa: Hanyar hakowa kuma tana shafar zaɓin bit. Idan kuna amfani da injin CNC, tabbatar da cewa bit ɗin ya dace da kayan aikin ku. Hakowa da hannu na iya buƙatar la'akari daban-daban, kamar ƙaramin rawar soja mai ƙarfi don jure matsi.

- KASAFIN KUDI: Duk da yake yana da ban sha'awa don zaɓar mafi arha mafi arha, saka hannun jari a cikin ƙaramin rawar gani mai inganci na iya ceton ku lokaci da kuɗi a cikin dogon lokaci. Rashin ingancin rawar soja na iya haifar da lalacewar allon kewayawa da kurakurai masu tsada.

A karshe

A cikin duniyar ƙirar PCB da masana'anta, kayan aikin da suka dace na iya yin komai. Ta hanyar fahimtar nau'ikan nau'ikan ramuka na katako na PC da aikace-aikacen su, zaku iya zaɓar mafi kyawun zaɓi don aikinku. Ko kai mai sha'awar sha'awa ne ko ƙwararre, saka hannun jari a cikin ingantacciyar rawar soja zai tabbatar da samar da PCB ɗinka tare da daidaito da aminci. Hakowa mai daɗi!

Lokacin aikawa: Janairu-07-2025