A cikin duniyar masana'antar lantarki mai sauri, inda madaidaicin matakin micron ke bayyana nasara, gabatarwar na gaba-Gen PCB Board Drill Bits alama ce ta tsalle-tsalle a cikin ƙirƙira hukumar kewayawa. An ƙera shi don yin hakowa, zane-zane, da micromachining akan allunan da'ira (PCBs) da sauran abubuwan da ba su da ƙarfi, waɗannan Karfe na Tungsten.Mini Drill PCBKayan aiki sun haɗu da kayan aikin sararin samaniya tare da fasahar kwanciyar hankali na girgizar ƙasa don sake fayyace inganci da tsawon rai a cikin samarwa mai girma.

Ingantaccen Injiniya: Me yasa Tungsten Karfe Mahimmanci

A tsakiyar waɗannan raƙuman rawar soja ya ta'allaka ne mai tsafta tungsten carbide (WC), kayan da aka zaɓa don haɗakar taurinsa mara misaltuwa (HRA 92), juriya, da amincin tsari. Ba kamar na al'ada HSS (High-Speed Steel) drills, wannan tungsten karfe dabaran isar:

3X Tsawon Rayuwa: Yana jurewa 15,000+ hawan hakowa akan allunan fiberglass FR-4 ba tare da lalata gefen ba.

Tsarin Micro-Grain: Sub-0.5µm hatsin carbide yana tabbatar da yankan gefuna masu kaifi, cimma diamita na rami kamar ƙanƙanta 0.1mm tare da ± 0.005mm haƙuri.

Designerarfin ƙwayar cuta: Sirricarfafa Shank Geometry yana hana cin hanci da kayan aiki (30,00000,000), har ma a cikin kayan tarihin PCB-Cert.

Gwajin ɓangare na uku ta Cibiyar Fasaha ta Mahimmancin Ma'aikata ta tabbatar da waɗannan raƙuman suna kiyaye Ra 0.8µm saman gama bayan ramukan 10,000 - muhimmin mahimmanci don ƙimar siginar mitoci a cikin na'urorin 5G da IoT.

Ƙarfin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙira

PCB hakowa yana buƙatar cikakken kwanciyar hankali don hana "tafiya" ko kuskuren rami. The Proprietary Seismic Blade Edge Design yana magance wannan ta hanyar:

Asymmetric Flute Geometry: Daidaita ƙaurawar guntu da damping na girgiza, rage ƙarfin gefe da kashi 40%.

Nano-Rufaffen Helix Angle: A 30 ° helix tare da TiAlN shafi rage zafi ginawa (<70°C) yayin ci gaba da aiki.

Anti-Resonance Grooves: Laser-etched micro-tashoshi suna lalata mitoci masu jituwa, suna tabbatar da daidaiton matsayi tsakanin 5µm a kan PCBs-Layer 10.

A cikin gwajin hako ramukan 0.3mm ta hanyar allunan aluminium 2mm, waɗannan raƙuman sun nuna karkacewar sifili sama da zagayowar 500 a jere - abin da masu fafatawa ba su yi kama da su ba.

Aikace-aikace a Faɗin Masana'antu

Kayan Wutar Lantarki na Masu Amfani

Ga masu kera wayar motherboard:

0.2mm Micro-Vias: An samu 99.9% yawan amfanin ƙasa akan allunan HDI mai Layer 12.

20% Ƙimar Ciyar da Sauri: An kunna ta ta hanyar rage juzu'i da guntuwar guntu.

Kayan Wutar Lantarki na Mota

A cikin samar da wutar lantarki ta EV:

Amincewa ta hanyar-Rami: Ci gaba da ci gaba da wutar lantarki 100% a cikin 1.6mm-kauri mai kauri mai ɗaukar hoto.

Aiki-Free Coolant: Ƙarfin hakowa bushe yana guje wa gurɓata tsarin sarrafa baturi.

Aerospace & Tsaro

Hako ramukan 0.15mm a cikin da'irori mai sassauƙa na polyimide:

Zero Delamination: Ko da a cikin 200°C babban mahalli mai zafi.

Tsarin Garkuwar EMI: Madaidaicin zane don yadudduka na garkuwar RF na tushen graphene.

Ƙididdiga na Fasaha

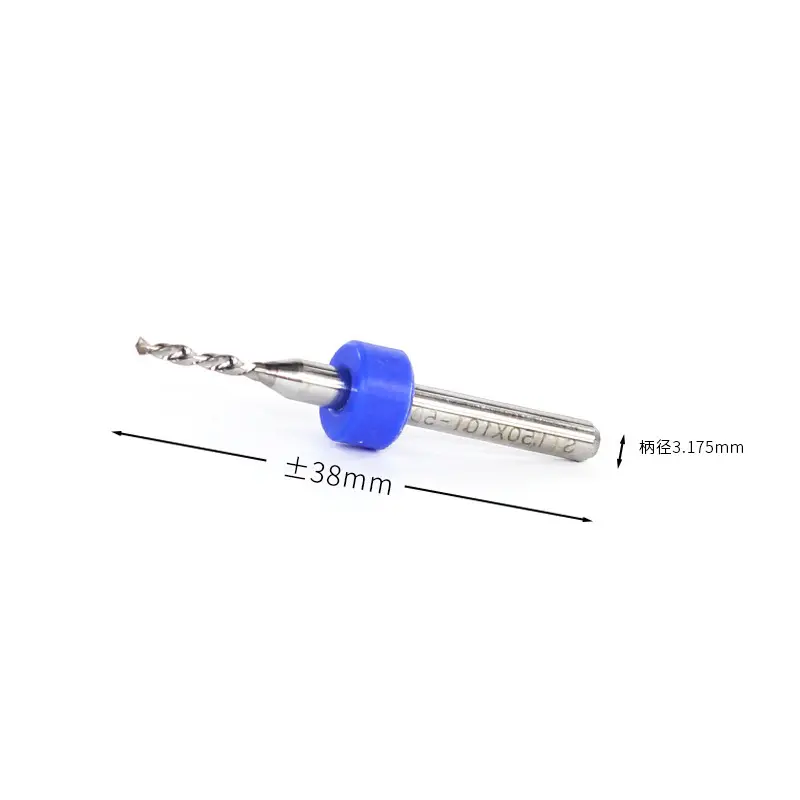

Nisa Nisa: 0.1mm-3.175mm (0.004"-1/8")

Nau'in Shank: Daidaitaccen 3.175mm (1/8") ko daidaituwar kwali na ER na al'ada

Zaɓuɓɓukan Rufi: TiN (zinariya), TiCN (blue), ko Carbon kamar Diamond-Kamar (DLC)

Matsakaicin RPM: 80,000 (dangane da diamita)

Daidaituwa: Injinan hakowa na CNC, PCB mai sarrafa motsi mai sarrafa kansa, kayan aikin rotary na hannu

An Sake Faɗin Ƙirar Kuɗi

Wani bincike mai fa'ida mai tsada ta babban mai ƙirƙira PCB na Taiwan ya bayyana:

$18,500 Taimakon Shekara-shekara: Rage sauye-sauyen rawar soja (daga saiti 12 zuwa 4 a shekara).

15% Rage Makamashi: Ƙananan buƙatun juzu'i na igiya.

Sake Aikin Sifili: An kawar da $220k/shekara a cikin allunan da aka goge daga yawo.

Dorewar Gina Cikin

Marufi Mai Sake Fa'ida: 100% tiren kumfa mai lalacewa.

RoHS & Isar da Yarda: Kyauta daga gubar, cadmium, da sauran abubuwa masu haɗari.

Rayuwar Kayan Aikin Ƙarfafa: 60% ƙananan amfani da tungsten vs. daidaitaccen drills.

Shaidar mai amfani

Hiroshi Tanaka, Manajan Samfura a wani ƙera na'urar firikwensin da ke Kyoto ya ce: "Canja zuwa waɗannan ɓangarorin ƙarfe na tungsten yana da canji." "Muna hako ramuka 20,000 a kowane lokaci ba tare da wani canji na kayan aiki ba - wani abu da ba za a iya misaltuwa ba tare da tsofaffin na'urorin mu na HSS. Tsarin girgizar kasa shi kadai ya yanke ramin mu da kashi 95 cikin dari."

Me yasa Zabi Waɗannan Ƙwaƙwalwar Hukumar PCB?

Ƙimar da ba za a iya karyewa ba: Don daidaito kamar Laser a cikin allunan haɗin haɗin kai mai girma (HDI).

Gudun Ba Tare da Hadaya: Haɗa ramukan 0.3mm a ramuka 400/minti ba tare da lalata ingancin gefen ba.

Daidaituwar Duniya: Yana aiki tare da FR-4, Rogers, aluminum, har ma da laminates masu ƙarfafa gilashi.

Zane-Hujja na gaba: Shirye don kayan PCB na gaba kamar su halogen-free da ultra-low-rass dielectrics.

Kammalawa

A cikin masana'antar inda kowane micron ke ba da riba da aiki, waɗannan Tungsten KarfePCB Board Drill Bitssun fi kayan aiki - fa'idar dabara ce. Ta hanyar haɗa ilimin kimiyyar kayan aiki tare da injiniyan kwanciyar hankali, suna ƙarfafa masana'antun don tura iyakokin ƙaranci yayin yankewa.

Lokacin aikawa: Maris 21-2025