A cikin masana'antu tun daga masana'antar kera motoci zuwa hada kayan lantarki, ƙalubalen samar da dorewa, zaren ƙarfi a cikin kayan bakin ciki ya daɗe yana addabar injiniyoyi. Hakowa na al'ada da hanyoyin bugawa sau da yawa suna lalata mutuncin tsarin ko buƙatar ƙarfafawa mai tsada. Shigar daFarashin M6 - bayani mai jujjuyawa-hakowa wanda ke ba da damar zafi, matsa lamba, da ingantacciyar injiniya don samar da zare masu ƙarfi a cikin kayan da bakin ciki kamar 1mm, ba tare da riga-kafi ko ƙarin abubuwan hakowa ba.

Kimiyya Bayan Flowdrill M6

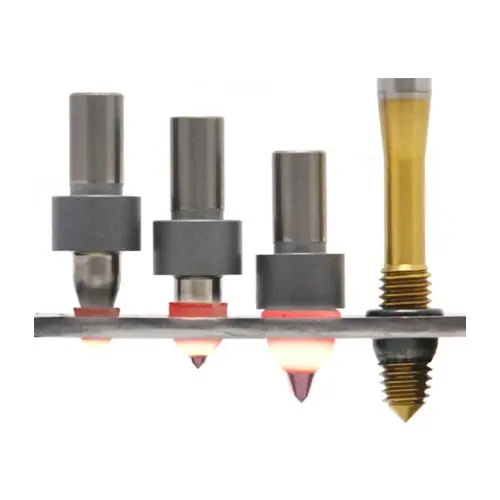

A ainihinsa, Flowdrill M6 yana amfani da hakowa na thermomechanical, tsari wanda ya haɗu da juyawa mai sauri (15,000-25,000 RPM) tare da matsa lamba axial mai sarrafawa (200-500N). Anan ga yadda yake jujjuya zanen gado na bakin ciki zuwa manyan zane-zane:

Heat Generation: Yayin da rawar-carbide-tipped ke hulɗa da kayan aikin, gogayya yana ɗaga yanayin zafi zuwa 600-800 ° C a cikin daƙiƙa, yana laushi kayan ba tare da narke shi ba.

Maɓallin Abu: Shugaban rawar sojan ya yi robobi kuma yana murkushe karfe, yana samar da bushing 3x ainihin kauri (misali, juya takardar 1mm zuwa shugaba mai zaren 3mm).

Haɗaɗɗen Zaren: Ginin famfo (M6×1.0 misali) nan da nan sanyi-samfurin madaidaicin zaren ISO 68-1 a cikin sabon abin wuya mai kauri.

Wannan aiki na mataki ɗaya yana kawar da matakai da yawa - ba buƙatun hakowa, reaming, ko bugun da ake buƙata.

Babban Fa'idodi Akan Hanyoyin Al'ada

1. Ƙarfin zaren da ba ya daidaita

300% Ƙarfafa Material: The extruded bushing ninki uku zurfin alkawari.

Ƙarfafa Aiki: Gyaran hatsi da ke haifar da raguwa yana ƙara taurin Vickers da kashi 25% a cikin yanki mai zaren.

Juriya-Fita: Gwaji yana nuna 2.8x mafi girman ƙarfin nauyin axial vs. yanke zaren a cikin 2mm aluminum (1,450N vs. 520N).

2. Daidaito Ba tare da Sassauta ba

± 0.05mm Daidaitaccen Matsayi: Tsarin ciyarwa na Laser yana tabbatar da daidaitaccen sanya rami.

Ra 1.6µm Surface Gama: Mai laushi fiye da zaren niƙa, yana rage lalacewa.

Ingancin Daidaitawa: Mai sarrafa zafin jiki / sarrafa matsi mai sarrafa kansa yana kiyaye juriya a cikin zagayowar 10,000+.

3. Kudi & Tsarar lokaci

80% Saurin Zagayowar Lokaci: Haɗa hakowa da zare cikin aiki na biyu-3-8.

Sarrafa Chip na Sifili: Haƙawar hakowa ba ta haifar da swarf, manufa don mahalli mai tsabta.

Tool Longevity: Tungsten carbide yi da jure ramukan 50,000 a bakin karfe.

Tabbatar da Aikace-aikacen Masana'antu

Mota Lightweighting

Babban masana'anta na EV sun karɓi Flowdrill M6 don taron tiren baturi:

1.5mm Aluminum → 4.5mm Mai Zauren Boss: Abubuwan da aka kunna M6 don amintattun fakitin baturi 300kg.

65% Rage Nauyi: Kawar da ƙwaya masu walda da faranti masu goyan baya.

Kashi 40% Tattalin Arziki: Rage $2.18 kowane sashi a cikin farashin aiki/masu ƙima.

Layin Jirgin Saman Jirgin Sama

Domin 0.8mm titanium ruwa conduits:

Hermetic Seals: Ci gaba da kwarara kayan abu yana hana ƙananan hanyoyi.

Resistance Vibration: Tsira da gwajin gajiya na zagaye 10 a 500Hz.

Kayan Wutar Lantarki na Masu Amfani

A cikin masana'antar chassis smartphone:

Matsakaicin Zare a cikin 1.2mm Magnesium: An kunna na'urori masu sirara ba tare da lalata juriya ba.

Garkuwar EMI: Rashin karyewar kayan abu a kusa da wuraren maɗaukaki.

Ƙididdiga na Fasaha

Girman Zaren: M6×1.0 (Custom M5-M8 akwai)

Dacewar Abu: Aluminum (1000-7000 jerin), Karfe (har zuwa HRC 45), Titanium, Copper Alloys

Kauri Sheet: 0.5-4.0mm (Madaidaicin kewayon 1.0-3.0mm)

Bukatun wutar lantarki: 2.2kW sandal motor, 6-bar sanyaya

Rayuwar Kayan aiki: 30,000-70,000 ramuka dangane da abu

Dorewa Edge

Ingantaccen Abu: 100% amfani - ƙarfe da aka kora ya zama ɓangaren samfurin.

Adana Makamashi: 60% ƙananan amfani da wutar lantarki vs. hakowa+tapping+welding tafiyar matakai.

Maimaituwa: Babu makamantan kayan (misali, abubuwan saka tagulla) da za a raba yayin sake yin amfani da su.

Kammalawa

Flowdrill M6 ba kayan aiki ba ne kawai - sauyi ne a cikin ƙirƙira kayan sirara. Ta hanyar canza raunin tsari zuwa kaddarorin da aka ƙarfafa, yana ƙarfafa masu ƙira don ƙara ƙara nauyi yayin kiyaye ƙaƙƙarfan ƙa'idodin aiki. Ga masana'antu inda kowane gram da micron ke ƙidayar, wannan fasaha ta haɗu da rata tsakanin ƙaranci da karko.

Lokacin aikawa: Maris 20-2025