Kashi na 1

An wuce gona da iri:

dalili:

1) Don billa mai yankan, kayan aikin ba su da ƙarfi kuma yana da tsayi ko ƙanƙanta, yana sa kayan aikin billa.

2) Rashin aiki mara kyau ta mai aiki.

3) Izinin yankan da ba daidai ba (misali: barin 0.5 a gefen gefen lanƙwasa da 0.15 a ƙasa) 4) Matsalolin yankan mara kyau (misali: haƙuri ya yi girma, saitin SF yana da sauri, da sauransu)

inganta:

1) Yi amfani da ka'idar yanke: yana iya zama babba amma ba ƙarami ba, yana iya zama gajere amma ba tsayi ba.

2) Ƙara hanyar tsaftace kusurwa, kuma kuyi ƙoƙarin kiyaye gefen kamar yadda zai yiwu (gefe a gefe da kasa ya kamata ya kasance daidai).

3) Daidaita daidaitattun sigogin yankan kuma zagaye sasanninta tare da manyan margins.

4) Yin amfani da aikin SF na kayan aikin injin, mai aiki zai iya daidaita saurin gudu don cimma mafi kyawun sakamako na kayan aikin injin.

Kashi na 2

Matsalar saitin kayan aiki

dalili:

1) Mai aiki ba daidai bane lokacin aiki da hannu.

2) Kayan aiki ba daidai ba ne.

3) Wurin da ke kan abin yankan tashi ba daidai ba ne (marar ta tashi da kanta tana da wasu kurakurai).

4) Akwai kuskure tsakanin R cutter, flat cutter da flying cutter.

inganta:

1) Ya kamata a bincika ayyukan da hannu a hankali akai-akai, kuma ya kamata a saita kayan aiki a daidai wannan wuri kamar yadda zai yiwu.

2) Lokacin shigar da kayan aiki, busa shi mai tsabta tare da bindigar iska ko goge shi da tsabta tare da rag.

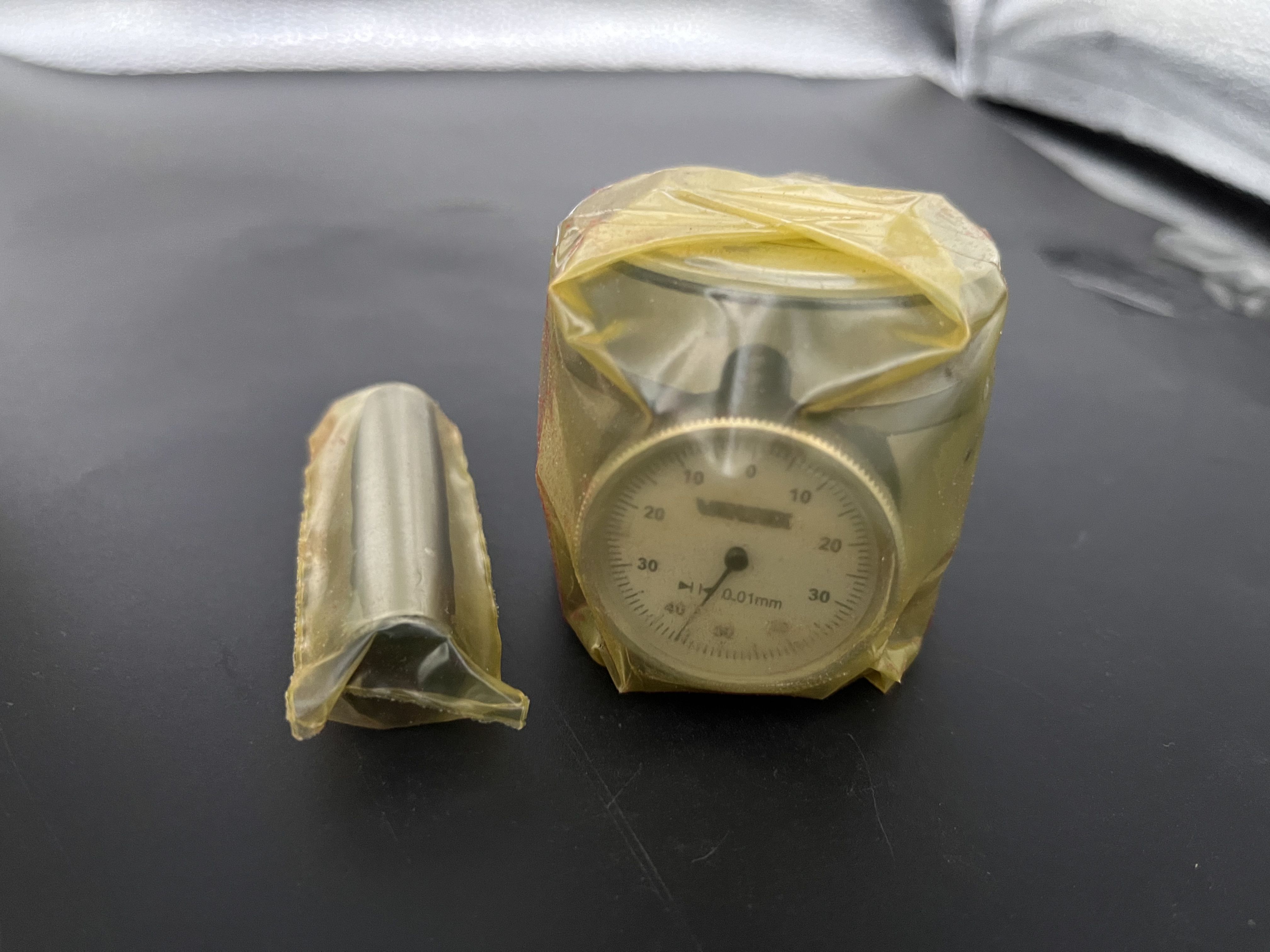

3) Lokacin da ruwan wukake akan abin yankan tashi yana buƙatar auna ma'aunin kayan aiki kuma an goge saman ƙasa, ana iya amfani da ruwa.

4) Hanyar saitin kayan aiki daban na iya guje wa kurakurai tsakanin mai yanke R, mai yankan lebur da mai yanke tashi.

Kashi na 3

Collider-Programming

dalili:

1) Tsayin aminci bai isa ba ko ba a saita shi ba (mai yankan ko chuck ya bugi kayan aiki yayin ciyarwar G00 mai sauri).

2) Kayan aiki akan jerin shirye-shiryen da ainihin kayan aikin shirin an rubuta su ba daidai ba.

3) Tsawon kayan aiki (tsawon ruwa) da ainihin zurfin aiki akan takardar shirin an rubuta ba daidai ba.

4) Zurfin Z-axis fetch da ainihin Z-axis fetch an rubuta ba daidai ba akan takardar shirin.

5) An saita haɗin kai ba daidai ba yayin shirye-shirye.

inganta:

1) Daidai auna tsayin aikin aikin kuma tabbatar da cewa tsayin aminci yana sama da workpiece.

2) Kayan aikin da ke cikin jerin shirye-shiryen dole ne su kasance daidai da ainihin kayan aikin shirin (kokarin amfani da jerin shirye-shirye na atomatik ko amfani da hotuna don samar da jerin shirye-shirye).

3) Auna ainihin zurfin aiki a kan workpiece, da kuma rubuta a fili tsawon da ruwa tsawon kayan aiki a kan takardar shirin (gaba daya kayan aiki matsa tsawon ne 2-3MM mafi girma daga workpiece, da ruwa tsawon 0.5-1.0MM).

4) Ɗauki ainihin lambar Z-axis akan aikin aikin kuma rubuta shi a fili akan takardar shirin. (Wannan aikin gabaɗaya an rubuta shi da hannu kuma yana buƙatar dubawa akai-akai).

Kashi na 4

Collider-Aiki

dalili:

1) Kuskuren saitin kayan aikin zurfafa Z axis ·.

2) An buga adadin maki kuma aikin ba daidai ba ne (kamar: ɗabo ɗaya ba tare da radiyon abinci ba, da sauransu).

3) Yi amfani da kayan aiki mara kyau (misali: amfani da kayan aikin D4 tare da kayan aikin D10 don sarrafawa).

4) Shirin yayi kuskure (misali: A7.NC ya tafi A9.NC).

5) Ƙaƙwalwar hannu tana juyawa ta hanyar da ba daidai ba yayin aiki da hannu.

6) Latsa hanyar da ba ta dace ba yayin tafiya cikin sauri ta hannu (misali: -X latsa +X).

inganta:

1) Lokacin yin saitin kayan aiki mai zurfi na Z-axis, dole ne ku kula da inda aka saita kayan aikin. (Tsarin ƙasa, saman saman, saman bincike, da sauransu).

2) Duba adadin hits da ayyuka akai-akai bayan kammalawa.

3) Lokacin shigar da kayan aiki, duba akai-akai tare da takardar shirin da shirin kafin shigar da shi.

4) Dole ne a bi shirin daya bayan daya.

5) Lokacin amfani da aikin hannu, mai aiki da kansa dole ne ya inganta ƙwarewarsa wajen sarrafa na'urar.

6) Lokacin motsi da hannu da sauri, zaku iya fara ɗaga axis Z zuwa aikin aikin kafin motsi.

Kashi na 5

Daidaiton saman

dalili:

1) A yankan sigogi ne m da workpiece surface ne m.

2) Yanke gefen kayan aiki ba shi da kaifi.

3) Ƙaƙwalwar kayan aiki ya yi tsayi da yawa kuma tsaurin ruwa ya yi tsayi da yawa.

4) Cire guntu, busa iska, da zubar da mai ba su da kyau.

5) Hanyar ciyar da kayan aiki na shirye-shirye (zaka iya gwada yin la'akari da milling).

6) Kayan aiki yana da burrs.

inganta:

1) Yanke sigogi, haƙuri, izini, saurin gudu da saitunan ciyarwa dole ne su kasance masu dacewa.

2) Kayan aiki yana buƙatar mai aiki don dubawa da maye gurbin shi lokaci zuwa lokaci.

3) Lokacin danne kayan aiki, ana buƙatar ma'aikacin ya kiyaye matse a matsayin gajere kamar yadda zai yiwu, kuma ruwan ruwa kada yayi tsayi da yawa don gujewa iska.

4) Don saukar da wukake masu lebur, wuƙaƙen R, da wuƙaƙen hanci, saurin gudu da saitunan abinci dole ne su kasance masu dacewa.

5) Kayan aikin yana da burrs: Yana da alaƙa kai tsaye da kayan aikin injin mu, kayan aiki, da hanyar ciyar da kayan aiki, don haka muna buƙatar fahimtar aikin injin ɗin kuma mu gyara gefuna tare da burrs.

Kashi na 6

tsinke baki

1) Ciyar da sauri-- sannu a hankali zuwa saurin ciyarwa mai dacewa.

2) Abincin yana da sauri a farkon yanke - rage saurin ciyarwa a farkon yanke.

3) Matsa sako-sako (kayan aiki) - matsa.

4) Matsa sako-sako (workpiece) - matsa.

5) Rashin isasshen ƙarfi (kayan aiki) - Yi amfani da mafi guntu kayan aiki da aka yarda, matsa hannun zurfin, kuma gwada niƙa.

6) Yanke gefen kayan aiki yana da kaifi sosai - canza kusurwar yankan mara ƙarfi, gefen farko.

7) Kayan aikin injin da mai riƙe da kayan aiki ba su da tsayi sosai - yi amfani da kayan aiki da kayan aiki da kayan aiki mai kyau.

Kashi na 7

lalacewa da tsagewa

1) Gudun injin yana da sauri sosai - rage gudu kuma ƙara isasshen mai sanyaya.

2) Abubuwan da aka taurare-yin amfani da kayan aikin yankan ci gaba da kayan aikin kayan aiki, da haɓaka hanyoyin jiyya na saman.

3) Chip adhesion - canza saurin ciyarwa, girman guntu ko amfani da mai sanyaya ko bindigar iska don tsaftace kwakwalwan kwamfuta.

4) Gudun ciyarwa bai dace ba (ƙananan yawa) - ƙara saurin ciyarwar kuma gwada ƙasa milling.

5) Kwangilar yankan bai dace ba - canza shi zuwa kusurwar yankan da ta dace.

6) Babban kusurwar taimako na farko na kayan aiki ya yi ƙanƙanta - canza shi zuwa kusurwar taimako mafi girma.

Kashi na 8

tsarin girgiza

1) Gudun ciyarwa da yankan suna da sauri--daidaita ciyarwar da saurin yankewa

2) Rashin isasshen ƙarfi (kayan injin da mai riƙe kayan aiki) - yi amfani da mafi kyawun kayan aikin injin da masu riƙe kayan aiki ko canza yanayin yanke.

3) kusurwar taimako ya yi girma sosai - canza shi zuwa ƙaramin kusurwar taimako kuma aiwatar da gefen (amfani da dutsen farar fata don haɓaka gefen sau ɗaya)

4) Matsa sako-sako-- matsa da workpiece

5) Yi la'akari da saurin gudu da adadin ciyarwa

Dangantakar da ke tsakanin abubuwa uku na sauri, ciyarwa da zurfin yanke shine mafi mahimmancin mahimmanci wajen ƙayyade tasirin yanke. Ciyarwar da ba ta dace ba da sauri sau da yawa tana haifar da raguwar samarwa, ƙarancin ingancin aikin aiki, da lalata kayan aiki mai tsanani.

Lokacin aikawa: Janairu-03-2024