Kashi na 1

Lokacin da ya zo ga mashin ɗin daidai, samun kayan aikin da suka dace yana da mahimmanci don samun ingantaccen sakamako mai inganci. Ɗaya daga cikin irin wannan kayan aiki wanda ba makawa a cikin masana'antar kera shine rawar carbide tabo. An san shi don tsayinta, daidaito, da juzu'insa, rawar carbide tabo ya zama dole ga kowane ƙwararren masani ko masana'anta. A cikin wannan labarin, za mu bincika fasali da fa'idodin MSK alamar carbide spot drills, da kuma dalilin da ya sa shi ne na ƙarshe kayan aiki ga machining machining.

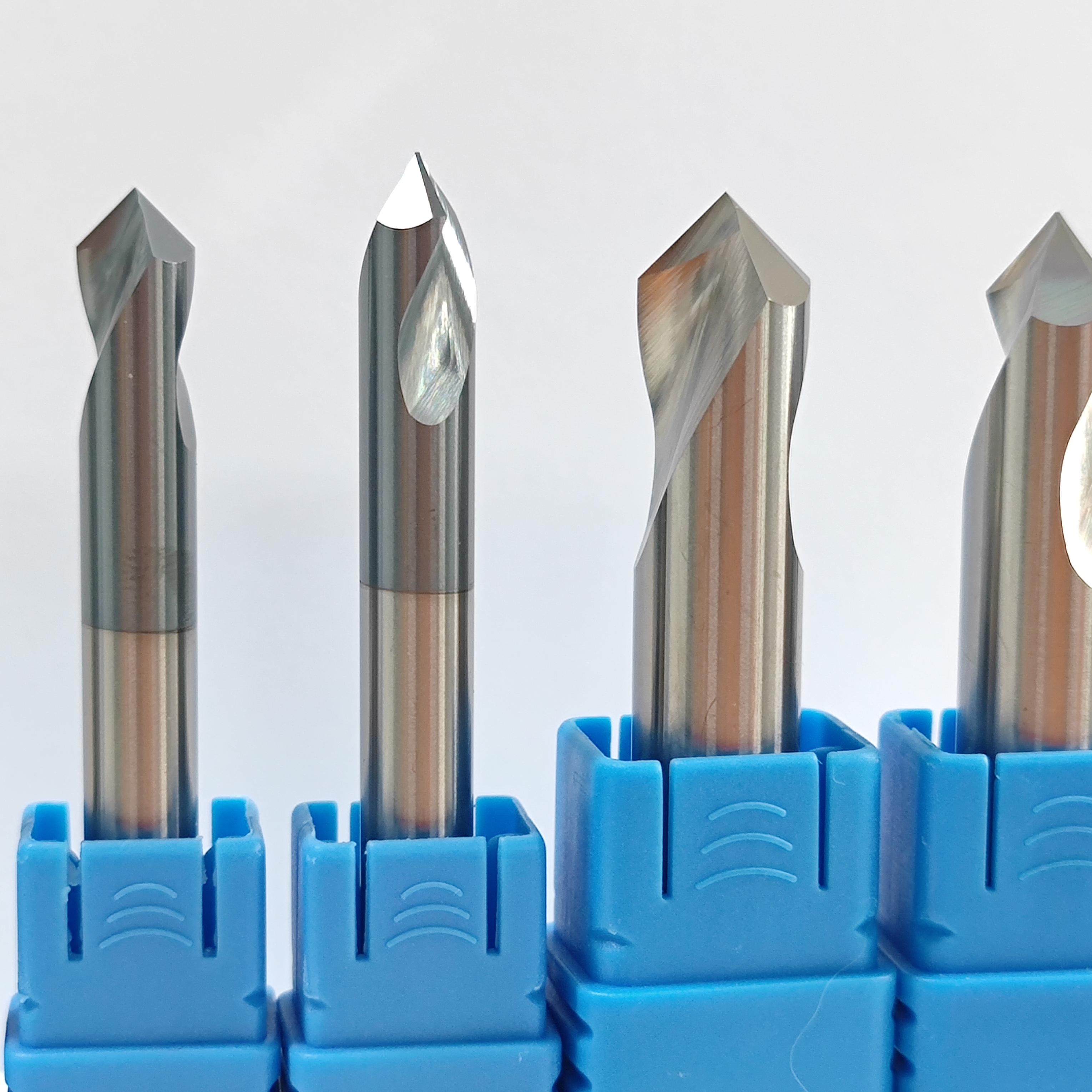

Alamar MSK carbide spot drillan tsara shi don biyan buƙatun aikace-aikacen injinan zamani. An yi shi da kayan aikin carbide mai inganci, wannan rawar rawar tabo yana ba da tauri na musamman da juriya, yana mai da shi dacewa da abubuwa da yawa, gami da ƙarfe, aluminum, da sauran gami. Yin amfani da carbide kuma yana tabbatar da cewa rawar jiki yana kiyaye kaifi da yankewa na tsawon lokaci, yana haifar da daidaitattun ayyukan injina.

Daya daga cikin key fasali naMSK alamar carbide spot drillshi ne na musamman na lissafin lissafi, wanda aka inganta don aikace-aikacen hakowa tabo. Ƙwallon yana fasalta tukwici mai nuni tare da takamaiman kusurwa, yana ba shi damar ƙirƙirar daidaitattun ramukan tabo tare da ɗan guntuwa ko ɓarna. Wannan yana da mahimmanci musamman a cikin ayyukan injina inda ƙirƙirar ramukan tabo mai tsabta da santsi yana da mahimmanci don aikin hakowa ko bugun gaba.

Kashi na 2

Baya ga mafi girman aikin yankan, daMSK alamar carbide spot drillHakanan an tsara shi don ƙaurawar guntu mai inganci. Ƙirar sarewa da ƙarfin fashewar guntu na rawar soja suna tabbatar da cewa an cire kwakwalwan kwamfuta yadda ya kamata daga yankin yankan, hana haɓaka guntu da rage haɗarin lalacewar kayan aiki ko lahani. Wannan fasalin yana da fa'ida musamman lokacin aiki tare da kayan da ke da saurin samuwar guntu, kamar bakin karfe ko gami da zafi mai zafi.

Bugu da ƙari, alamar MSK alamar carbide spot drill yana samuwa a cikin kewayon girma da diamita, ƙyale masanan injiniyoyi su zaɓi kayan aiki mafi dacewa don ƙayyadaddun bukatun aikace-aikacen su. Ko don ƙirƙirar ƙananan, daidaitattun ramukan tabo ko mafi girman diamita, ƙwarewar aikin tabo na carbide ya sa ya zama kadara mai mahimmanci a kowane yanayi na inji. Bugu da ƙari, samun nau'ikan nau'ikan shank daban-daban, irin su madaidaiciyar shank ko taper Morse, yana ƙara haɓaka daidaituwar rawar soja tare da saitin injin daban-daban da tsarin riƙe kayan aiki.

Kashi na 3

Wani sanannen amfani daMSK alamar carbide spot drillshine tsawon rayuwar kayan aiki da karko. Haɗuwa da kayan aikin carbide mai inganci da fasahohin sutura masu haɓaka suna haifar da rawar jiki wanda zai iya jure buƙatun mashin ɗin sauri da aikace-aikacen nauyi. Wannan tsayin daka ba kawai yana rage farashin maye gurbin kayan aiki ba amma har ma yana ba da gudummawa ga yawan aiki da inganci a cikin aikin injin.

Idan ya zo ga mashin daidaici, daidaito da maimaitawa sune mafi mahimmanci. Alamar tambarin carbide ta alama ta MSK ta yi fice a cikin isar da daidaito kuma daidaitaccen sakamako, godiya ga tsayayyen gininsa da ingantaccen aikin yankewa. Masana injiniyoyi na iya dogara da wannan kayan aikin don cimma matsananciyar haƙuri da ƙarewar saman ƙasa, tabbatar da cewa kayan aikin injin ɗin su sun dace da ƙayyadaddun ƙayyadaddun da ake buƙata da ƙa'idodin inganci.

A ƙarshe, MSK alamar carbide tabo rawar soja babban kayan aiki ne wanda ke ba da aiki na musamman da amincin aikace-aikacen injina. Ƙarfinsa na yankewa, ingantaccen ƙaurawar guntu, juzu'i, da dorewa sun sa ya zama kadara mai mahimmanci ga masana'anta da ƙwararrun masana'antu. Ko don ƙirƙirar ramukan tabo, chamfering, ko countersinking, aikin tabo na carbide yana ba da daidaito da daidaiton da ake buƙata don haɓaka ayyukan injin zuwa mataki na gaba. Tare da rawar gani na carbide ta alama ta MSK a cikin arsenal ɗinsu, masana'antun za su iya yin ƙarfin gwiwa da ƙarfin gwiwa don magance nau'ikan ayyukan injina tare da daidaito da inganci.

Lokacin aikawa: Afrilu-26-2024