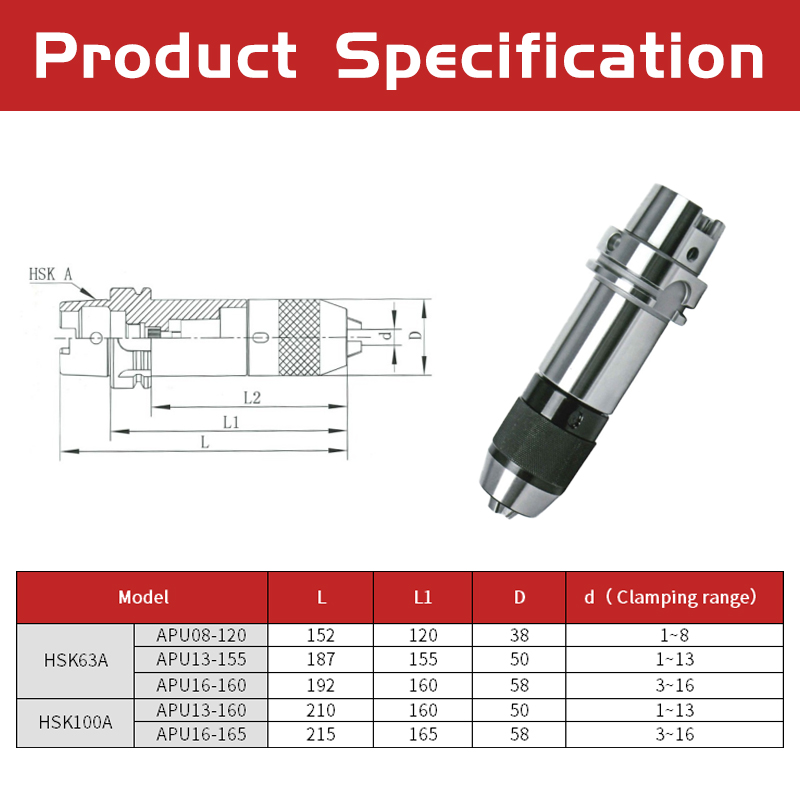

Factory On Sale HRC58-60 HSK63A APU16-160 Integral Shank Drill Chuck

| Brand | MSK | OEM | YES |

| Material | 20CrMnTi | Usage | Cnc Milling Machine Lathe |

| MOQ | 10 PCS | Type | HSK63A HSK100A |

The Versatility of Integrated Drill Chuck

When it comes to precision machining, the choice of tooling system plays a critical role in ensuring accuracy, performance and efficiency. One of the key components in a machining setup is the drill chuck holder, which securely holds the cutting tool in place. Among the various options available, integrated drill chuck holders (especially the HSK63a APU) are gaining attention for their versatility and reliability. In this article, we'll take an in-depth look at the features and benefits of using the HSK63a APU drill chuck holder, a highly sought after tooling system in manufacturing.

Integrated drill chuck holders:

An integrated drill chuck fixture is a mechanical device designed to securely clamp a cutting tool and transmit torque during machining operations. HSK (Hollow Shank Taper) is a widely accepted standard for tool holders in CNC machines. The HSK63a APU is an integrated drill chuck holder that combines the best features of the HSK and APU systems to provide superior precision, stability and rigidity.

Versatility of the HSK63a APU:

With its innovative design, the HSK63a APU drill chuck holder offers versatility to accommodate a wide variety of cutting tools. This adaptability enables machinists to use a single tool system for a variety of operations, including drilling, milling and tapping. Manufacturers save time and increase productivity by eliminating the need for multiple setups or tool changes.

Stability and Accuracy:

HSK63a APU provides excellent stability with its rigid structure and reliable clamping mechanism, minimizing tool displacement during high-speed machining. The precision of this drill chuck fixture ensures consistent and accurate cuts, reducing the chance of error and rework.

Time saving solution:

Integrating the APU mechanism with the HSK63a further simplifies tool changes, saving time. The APU (Adjustable Projection Unit) feature allows for easy adjustment of tool projection length, optimizing cutting performance and reducing setup time. Additionally, the quick tool change feature allows for a seamless transition from one operation to another, maximizing machine utilization.

in conclusion:

Integrated drill chuck holders have become an indispensable tooling system in the ever-evolving manufacturing industry. Among its variants, the HSK63a APU drill chuck holder stands out as a versatile, reliable and time-saving solution. Its ability to accommodate a wide range of cutting tools, coupled with stability and precision, make it the first choice for machinists looking for the best possible results. By considering the advantages of integrated drill chuck fixtures such as the HSK63a APU, manufacturers can take the efficiency and productivity of their machining processes to new levels.