Factory Direct Sales High-Precision Excellent Quality ER Collet Nut

| Brand | MSK | Packing | Plastic box or other |

| Material | 40CrMo | Usage | Cnc Milling Machine Lathe |

| Size | 151mm-170mm | Type | NOMURA P8# |

| Warranty | 3 months | Customized support | OEM,ODM |

| MOQ | 10 Boxes | Packing | Plastic box or other |

ER Collet Nuts are an important component used to securely hold cutting tools or workpieces in place during machining operations. By clamping the collet securely around the tool or workpiece, ER collet nuts ensure stability and precision during machining.

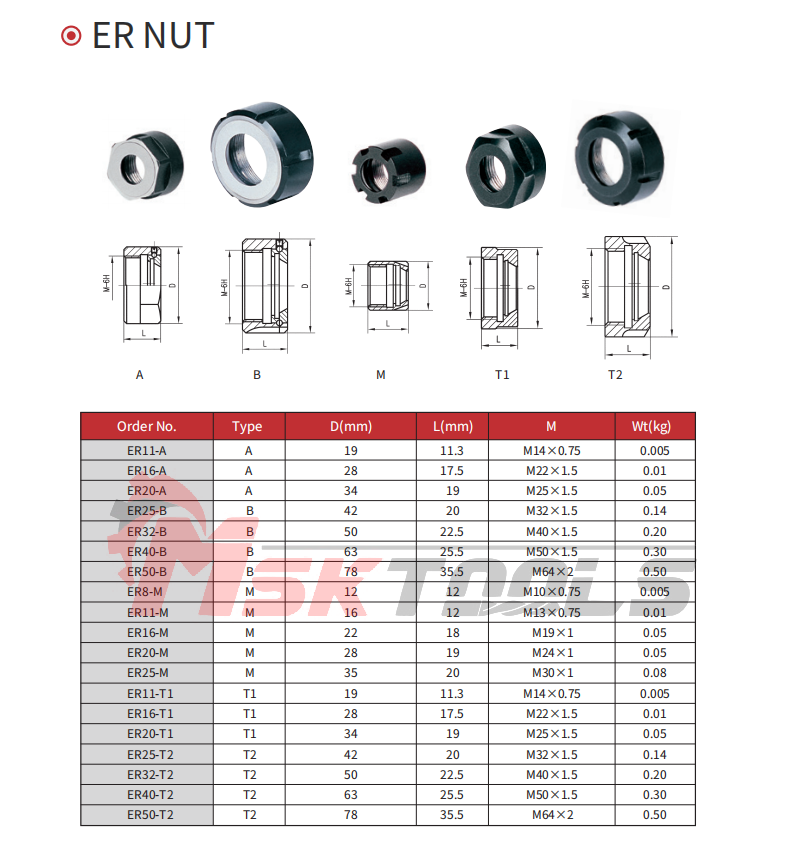

Various ER nut sizes are available in the market to accommodate different collet sizes. ER nuts are manufactured to fit specific collets and it is important to select the correct size to ensure a proper fit. Compatibility between ER nuts and collets is critical to the efficiency and success of machining operations.

Collet clamping nuts, also known as ER nuts, come in different sizes to match the corresponding collet size. ER nuts are available in a variety of sizes. Selecting the correct ER nut size is very important as it directly affects the efficiency and accuracy of machining operations. Using incorrect dimensions can result in poor clamping, which can lead to tool slippage, loss of accuracy and increased risk of accidents. Therefore, it is critical to determine the proper ER nut size for the collet and tool size being used.

In addition to the ER nut size, the quality of the ER collet nut itself is also important. Nuts should be made of a high-quality material such as steel to ensure durability and longevity. A well-made ER nut will provide reliable clamping force and meet the requirements of the machining process.

In conclusion, ER collet nuts are important components in machining operations. Selecting the correct ER nut size (eg ER 32 or ER 16) is critical for proper tool clamping and precise machining. Both ER nut size and quality need to be considered to ensure efficient and accurate machining results.