Durable HSK63A-FMHC Anti-vibration damping tool handle for CNC Boring Applications

Introducing the ultimate shock-absorbing tool: the anti-vibration dampened tool handle for CNC boring bar tool holders

In the field of precision machining, achieving excellent surface finish and high efficiency in deep hole machining is crucial. Our latest innovation: an anti-vibration damped tool handle specially designed for CNC boring bar tool holders. This cutting-edge tool is designed to revolutionize your machining experience by effectively reducing vibration, improving surface quality and maximizing productivity.

Unparalleled shock absorption

Vibration is one of the biggest challenges machinists face, especially when machining deep holes. Excessive vibration can lead to poor surface finish, increased tool wear, and even catastrophic tool failure. Our anti-vibration dampened tool handles are engineered to address these issues. The tool handle features advanced damping technology that absorbs and dissipates vibration, ensuring your cutting tool maintains optimal contact with the workpiece. What was the result? Surface finish is significantly improved and processing time is significantly reduced.

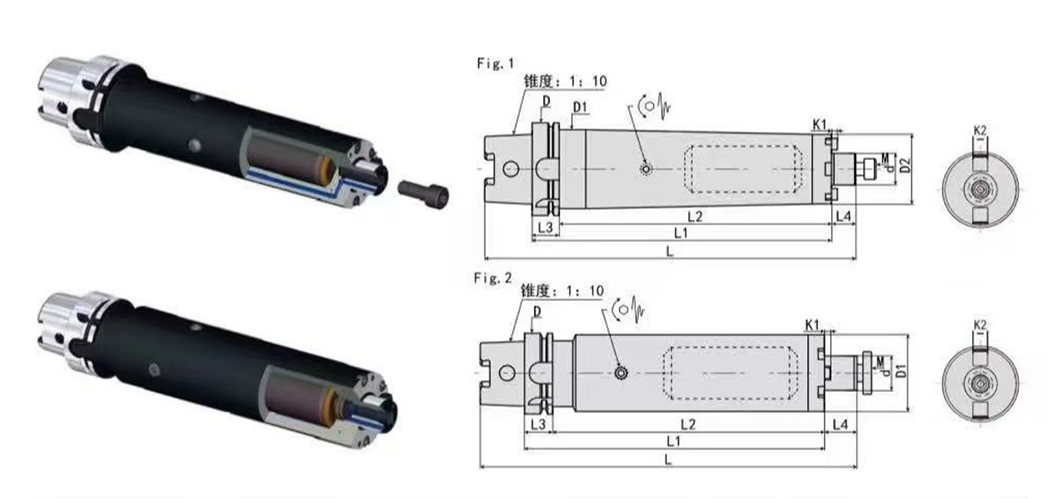

HSK63A-FMHC DAMPING MILLING TOOL HOLDER

| Model | L | L1 | L2 | L3 | L4 | D | D1 | D2 | d | K1 | K2 | M |

| HSK63A-FMHC16-150-D37 | 199 | 150 | 124 | 26 | 17 | 63 | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -200-D37 | 249 | 200 | 174 | 26 | 17 | 63 | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -250-D37 | 299 | 250 | 224 | 26 | 17 | 63 | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -300-D37 | 349 | 300 | 274 | 26 | 17 | 63 | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -350-D37 | 399 | 350 | 324 | 26 | 17 | 63 | 40 | 37 | 16 | 3.2 | 8 | M8*1.25P |

| -FMHC22-150-D47 | 200 | 150 | 124 | 26 | 17 | 63 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -200-D47 | 250 | 200 | 174 | 26 | 17 | 63 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -250-D47 | 300 | 250 | 224 | 26 | 18 | 63 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -300-D47 | 350 | 300 | 274 | 26 | 18 | 63 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -350-D47 | 400 | 350 | 324 | 26 | 18 | 63 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -400-D47 | 450 | 400 | 374 | 26 | 18 | 63 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -450-D47 | 500 | 450 | 424 | 26 | 18 | 63 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -500-D47 | 550 | 500 | 474 | 26 | 18 | 63 | 50 | 47 | 22 | 4.8 | 10 | M10*1.25P |

| -FMHC27-200-D60 | 252 | 200 | 174 | 26 | 20 | 63 | 60 | 27 | 5.8 | 12 | M12*1.75P | |

| -250-D60 | 302 | 250 | 224 | 26 | 20 | 63 | 60 | 27 | 5.8 | 12 | M12*1.75P | |

| -300-D60 | 352 | 300 | 274 | 26 | 20 | 63 | 60 | 27 | 5.8 | 12 | M12*1.75P | |

| -350-D60 | 402 | 350 | 324 | 26 | 20 | 63 | 60 | 27 | 5.8 | 12 | M12*1.75P | |

| -400-D60 | 452 | 400 | 374 | 26 | 20 | 63 | 60 | 27 | 5.8 | 12 | M12*1.75P | |

| -450-D60 | 502 | 450 | 424 | 26 | 20 | 63 | 60 | 27 | 5.8 | 12 | M12*1.75P | |

| -500-D60 | 552 | 500 | 474 | 26 | 20 | 63 | 60 | 27 | 5.8 | 12 | M12*1.75P |

HSK63A - Shank size

FMHC - Holder type

16 - Bore diameter of cutter

150 - Length(L1)

D37 - Diameter

Why Choose Us

Factory Profile

About Us

FAQ

Q1: who are we?

A1: Founded in 2015, MSK (Tianjin) Cutting Technology CO.Ltd has grown continuously and passed Rheinland ISO 9001

authentication.With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end,professional and efficient CNC tool.

Q2: Are you trading company or manufacturer?

A2: We are the factory of carbide tools.

Q3: Can you send products to our Forwarder in China?

A3: Yes,if you have Forwarder in China,we will glad to send products to him/her.Q4: What terms of payment are acceptable?

A4: Normally we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, and we also provide label printing service.

Q6: Why should you choose us?

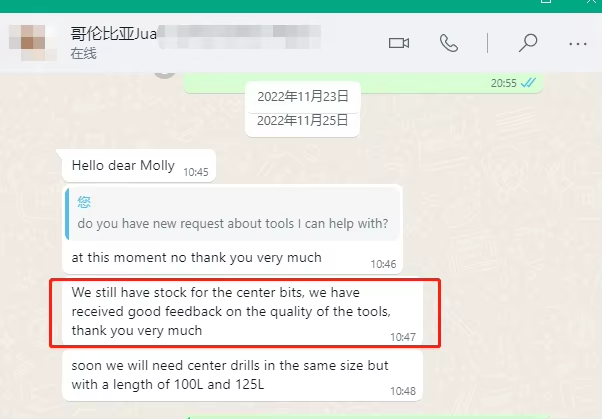

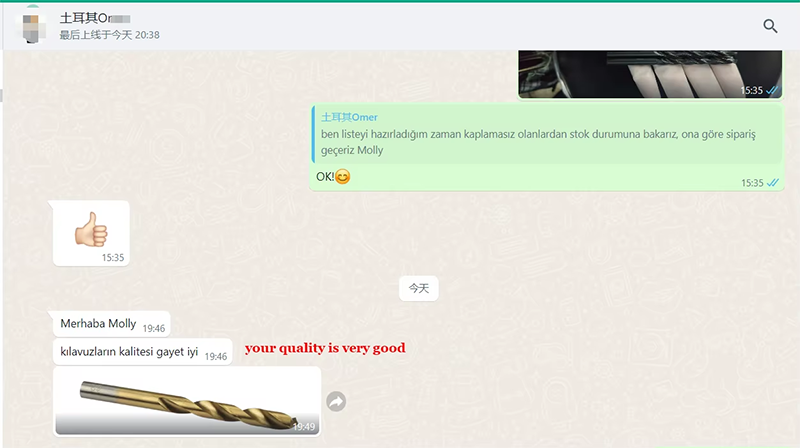

A6:1) Cost control - purchasing high-quality products at an appropriate price.

2) Quick response - within 48 hours, professional personnel will provide you with a quote and address your concerns.

3) High quality - The company always proves with sincere intention that the products it provides are 100% high-quality.

4) After sales service and technical guidance - The company provides after-sales service and technical guidance according to customer requirements and needs.