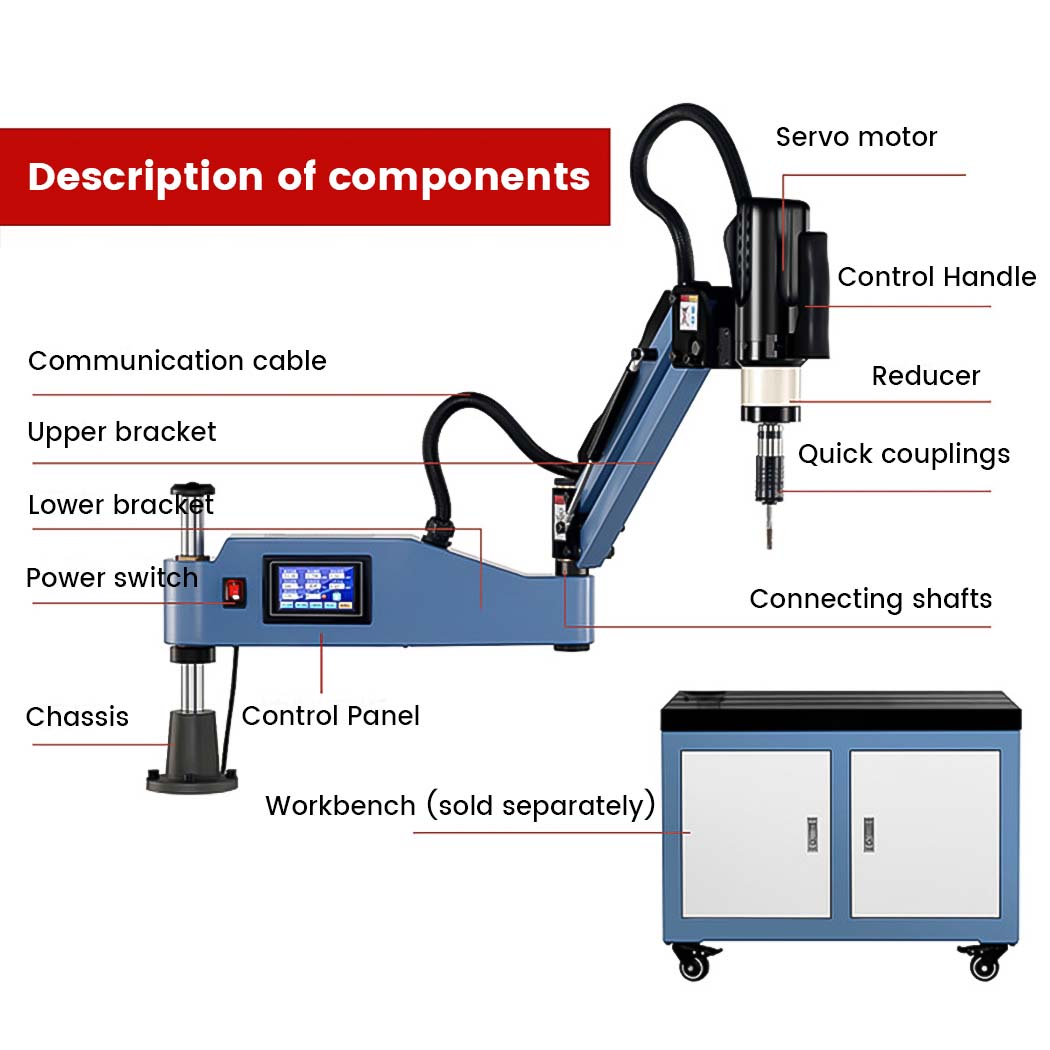

CNC Hydraulic Automatic Flex Arm Drilling Tapping Machine Vertical/Universal

In the ever-evolving world of manufacturing and machining, the need for precision, efficiency and versatility has never been more important. The CNC Electric Tapping Arm Machine is one of them, a state-of-the-art solution designed to meet the demands of a modern production environment. This innovative machine combines advanced technology with user-friendly features, making it a must-have tool for both light and heavy-duty operations.

Unrivaled Performance and Efficiency

The heart of the CNC electric tapping arm machine is its sturdy swing-arm stand and high-performance servo motor. This combination ensures high tapping efficiency and flexible operation, allowing the user to move the machine to different workstations effortlessly. Whether you are using through-hole or blind-hole taps, the machine guarantees precision and reliability, minimizing the risk of tap damage and ensuring a longer service life.

| Product Specification | Working Voltage | Working radius | Number of collets | Motor power | Working speed | Tapping range | Tapping capacity |

| M3-10E Tapping Machine Vertical / Universal | 220V | 1000MM | National standard 5 pcs | 600W | 1000 RPM | M3-10 | Steel/stainless steel <M8 iron/aluminum/copper <M10 |

| M3-12E Vertical/Universal Tapping Machine | 220V | 1000MM | National standard 6 pcs | 600W | 625 RPM | M3-12 | Steel/stainless steel <M10 iron/aluminum/copper <M12 |

| M3-16E Vertical/Universal Tapping Machine | 220V | 1000MM | National standard 8 pcs | 600W | 312 RPM | M3-M16 | Steel/stainless steel <M14 iron/aluminum/copper <M16 |

| M3-20E Vertical/Universal Tapping Machine | 220V | 1000MM | National standard 9 pcs | 800W | 200 RPM | M3-M20 | Steel/stainless steel <M18 iron/aluminum/copper <M20 |

| M3-20ED High Power Tapping Machine Vertical / Universal | 220V | 1200MM | National standard 9 pcs | 1200W | 625 RPM | M3-M20 | Steel/stainless steel <M20 iron/aluminum/copper <M20 |

| M6-24E Vertical / Universal Tapping Machine | 220V | 1200MM | National standard 8 pcs | 1200W | 200 RPM | M6-M24 | Steel/stainless steel <M22 iron/aluminum/copper <M24 |

| M6-30E Tapping Machine Vertical / Universal | 220V | 1200MM | National standard 9 pcs | 1200W | 200 RPM | M6-M30 | Steel/stainless steel <M27 iron/aluminum/copper <M30 |

| M6-36E Tapping Machine Heavy Straight / Universal | 220V | 1200MM | National standard 11 pcs | 1200W | 156 RPM | M6-M36 | Steel/stainless steel <M33 iron/aluminum/copper <M36 |

Our key differentiators

1. Stable torque and long service life: CNC electric tapping arm machines are designed to provide stable torque, which not only improves the quality of the tapping process but also extends the service life of the machine. This stability is essential to maintain consistent performance in a variety of applications.

2. Fast Repeat Positioning: With its fast repeat positioning function, the machine can achieve fast cutting and high productivity. Operators can get precise results in a shorter time, which significantly improves the overall efficiency of the production line.

3. Safety and Precision: Safety is paramount in any machining operation. The CNC electric tapping arm machine features a simple clamping mechanism that ensures minimal damage to the taps. This design enables high-precision tapping operations, making it suitable for a wide range of materials and applications.

4. Versatile Work Range: One of the standout features of this machine is its wide work range. It can accommodate heavier workpieces without constant repositioning, saving the operator time and effort. This versatility makes it ideal for a variety of industries, from automotive to aerospace.

5. User-friendly Operation: Designed with the operator in mind, the CNC electric tapping arm machine is lightweight and easy to operate. Its intuitive controls reduce work intensity, allowing users to focus on achieving high-quality results without unnecessary stress.

The future of tapping technology

As the requirements for efficiency and precision continue to increase in all walks of life, CNC electric tapping arm machine stands out as a leading solution. It combines advanced servo technology and flexible operation, bringing revolutionary changes to manufacturers seeking to enhance the tapping process.

Whether you are a small shop or a large manufacturing plant, this machine can meet your needs and provide a reliable and efficient tapping solution. Experience the difference that the CNC electric tapping arm machine can bring to your operation and take your production capabilities to new heights.

In conclusion, if you are looking for a servo electric tapping machine or curved arm tapping machine that offers unmatched performance, safety and ease of use, then the CNC electric tapping arm machine is your best choice. Invest in the future of your machining business today and witness a transformation in your productivity and precision.

Why Choose Us

Factory Profile

About Us

FAQ

Q1: who are we?

A1: Founded in 2015, MSK (Tianjin) Cutting Technology CO.Ltd has grown continuously and passed Rheinland ISO 9001

authentication.With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end,professional and efficient CNC tool.

Q2: Are you trading company or manufacturer?

A2: We are the factory of carbide tools.

Q3: Can you send products to our Forwarder in China?

A3: Yes,if you have Forwarder in China,we will glad to send products to him/her.Q4: What terms of payment are acceptable?

A4: Normally we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, and we also provide label printing service.

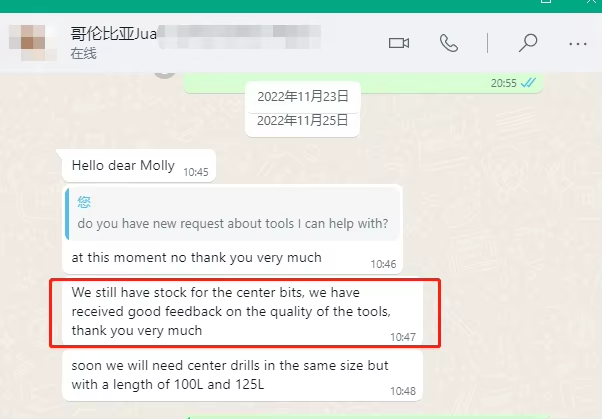

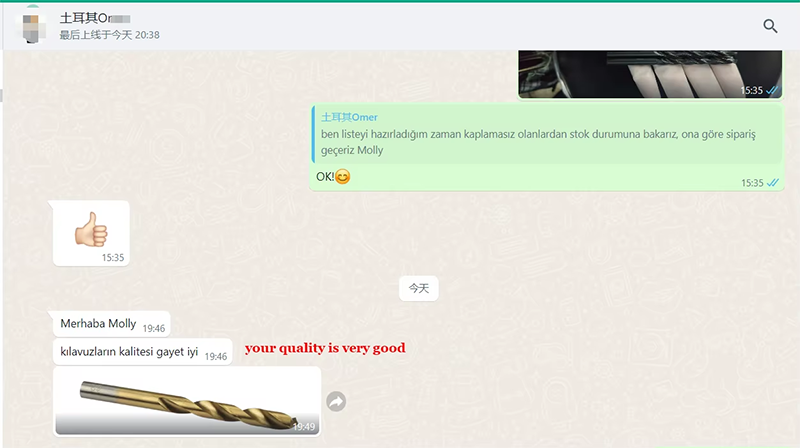

Q6: Why should you choose us?

A6:1) Cost control - purchasing high-quality products at an appropriate price.

2) Quick response - within 48 hours, professional personnel will provide you with a quote and address your concerns.

3) High quality - The company always proves with sincere intention that the products it provides are 100% high-quality.

4) After sales service and technical guidance - The company provides after-sales service and technical guidance according to customer requirements and needs.