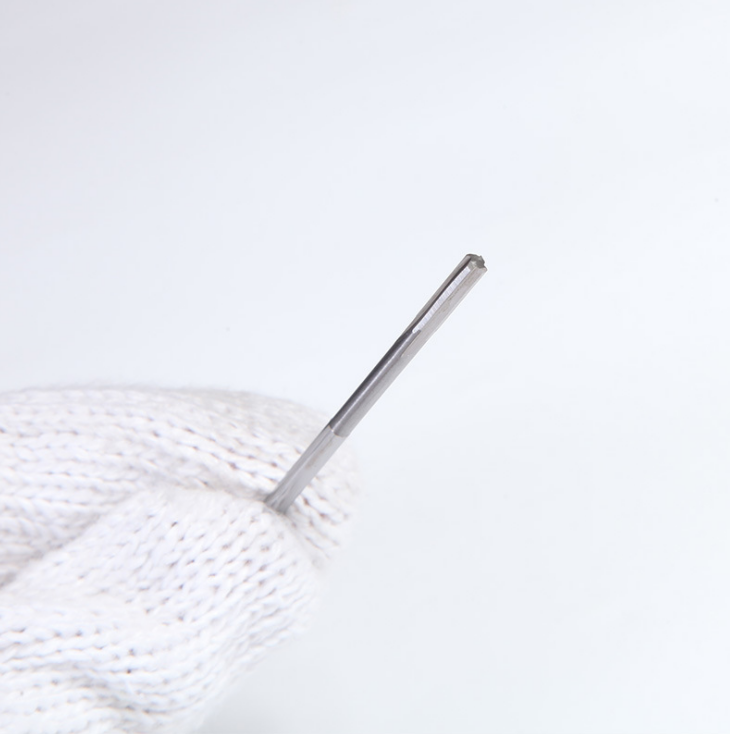

China wholesale Spiral Taper Reamer - Straight Flute Shank Straight Reamer – MSK

China wholesale Spiral Taper Reamer - Straight Flute Shank Straight Reamer – MSK Detail:

Suitable for processing chilled alloy cast iron and heat-resistant alloy steel, and precision processing of ordinary cast iron with high wear resistance. It can finish the hole, which is higher than the machining precision of the general reamer and suitable for general machine tools.

Straight Flute Reamers are for general use. Best used in non- chip forming materials such as cast iron, bronze and free cutting brass. The preferred hole type for Straight Fluted Reamers is a through hole but they do perform well in blind holes due to their non aggressive geometry.

Available in Carbide, Carbide Tipped, HSS and HSCo in Standard and Long Series.

Product Introduction

the chucking reamers are sharp, sturdy and strong wear resistance for long service life.

Used for semi-finish machining and finish machining of holes. Suitable for stainless steel, carbon steel, cast iron, die steel, alloy steel, tool steel and non-ferrous materials.

The reamer is with more cutter teeth. Holes can get exact size and shape after the reamers’ processing. Finished products are smooth, intact and more beautiful.

Applications

Can be used for processing holes, mainly to improve machining precision of holes

| Flutes | 4/6 |

| Workpiece Material | Copper, stainless steel, aluminum, plastic, wood, titanium alloy |

| Type | Flat Head |

| Material | Carbide Alloy |

| Coating | Yes |

| Type Of Handle | Straight |

| Package | 1pc/plastic box |

| Brand | MSK |

| Flute Diameter D | Flute Length L1 | Shank Diameter d | Length L |

| 3 | 30 | 3 | 60 |

| 4 | 30 | 4 | 60 |

| 5 | 30 | 5 | 60 |

| 6 | 30 | 6 | 60 |

| 8 | 40 | 8 | 75 |

| 10 | 45 | 10 | 75 |

| 12 | 45 | 12 | 75 |

Advantage:

1.Ultra wide capacity chip removal makes powerful cutting, smoother chip discharge, high-speed machining, higher precision and luster of tools.

2.Higher hardness

3.no dust pollution.

Use

Aviation Manufacturing

Machine Production

Machine Production

Car manufacturer

Car manufacturer

Mold making

Electrical Manufacturing

Lathe processing

Lathe processing

Product detail pictures:

Related Product Guide:

We strive for excellence, service the customers", hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for China wholesale Spiral Taper Reamer - Straight Flute Shank Straight Reamer – MSK , The product will supply to all over the world, such as: United Arab emirates, Russia, Germany, We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!