Best Benchtop Drill Press For Milling Drilling

Product information

| Product information | |

|

Origin |

China Mainland |

|

Brand |

MST |

|

Power Type |

AC power |

|

Voltage |

380v/220v |

|

Power |

550~1500(W) |

|

Rated voltage range |

AC three-phase 440V and below |

Product model and parameters

| model: | Z4120 (heavy) |

| Maximum drilling diameter (mm) | 20 |

| Column diameter (mm) | 70 |

| Max stroke of spindle (mm) | 85 |

| Distance from spindle center to column surface (mm) | 200 |

| Maximum distance from spindle end to work table (mm) | 320 |

| Maximum distance from spindle end to base table (mm) | 490 |

| Spindle taper | MT2 |

| Spindle speed range (r/min) | 280-3100 |

| Spindle speed series | 4 |

| Work table size (mm) | 230*240 |

| Base size (mm) | 310*460 |

| Motor (w) | 750 |

| Gross weight/Net weight (kg) | 60/57 |

| model | Z516 |

| Maximum drilling diameter (mm) | 16 |

| Column diameter (mm) | 60 |

| Max stroke of spindle(mm) | 85 |

| Distance from spindle center to column surface (mm) | 190 |

| Maximum distance from spindle end to work table (mm) | 270 |

| The maximum distance from the spindle end to the base table (mm) | 390 |

| Spindle taper | B16 |

| Spindle speed range (r/min) | 480-1400 |

| Spindle speed series | 4 |

| Work table size (mm) | 200*200 |

| Base size (mm) | 300*430 |

| Motor (w) | 550 |

| Gross weight/Net weight (kg) |

35/40 |

| model | ZX7016 |

| Maximum drilling diameter (mm) | 20 |

| Maximum end milling width (mm) | 30 |

| Maximum vertical milling diameter (mm) | 8 |

| Column diameter (mm) | 70 |

| Max stroke of spindle(mm) | 85 |

| Distance from spindle center to column busbar (mm) | 200 |

| Maximum distance from spindle end to work table (mm) | 400 |

| The maximum distance from the spindle end to the base table (mm) | 520 |

| Spindle taper | MT3 |

| Spindle speed range (r/min) | 387-5350 |

| Spindle speed series | 4 |

| Work table size (mm) | 450*170 |

| Table stroke (mm) | 265-135 |

| Base size (mm) | 320*480 |

| Overall height(mm) | 920 |

| Main motor (w) | 1500 |

| Gross weight/Net weight (kg) | 80/85 |

| Packing size(mm) | 330*650*750 |

FEATURE

1. Wide application, super practical. Suitable for metal processing, wood, aluminum and iron processing, construction site processing and repair and manufacturing industries

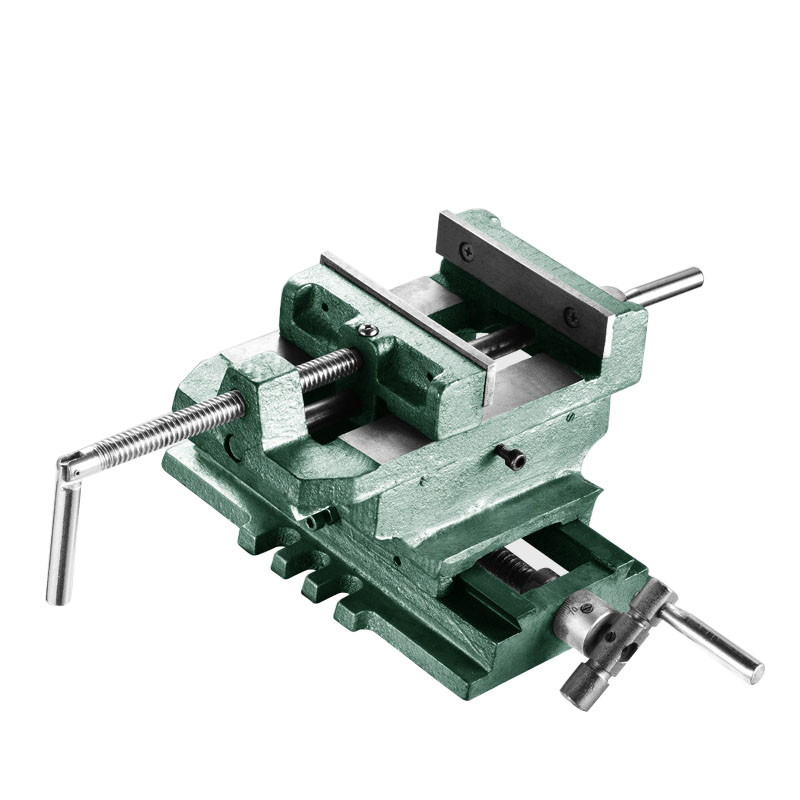

2. Seiko manufacturing, new upgrade. Equipped with a cross table, one second to change the milling machine

3. High-quality belt, durable and wear-resistant, using Seiko durable belt, excellent balance performance

4. High-precision chuck, high-precision scale, high-efficiency motor, high-thickness base.

5. All-steel handle, turn to work. Quality material selection, easy operation, long service life

6. Removable cross worktable, can be equipped with cross worktable, dual-purpose drilling and milling, can be converted at will

7. High-quality lifting handwheel, easy to operate. Loosen the headstock lock, select the lifting handwheel to complete the lifting

8. Thickened and heavier, industrial-grade flat-nose pliers. High-quality steel, silky smooth rod, more convenient to use

9. Precision cross vise. Cross sliding guide, stable clamping and high hardness